精密セラミックスの紹介

重要性と用途

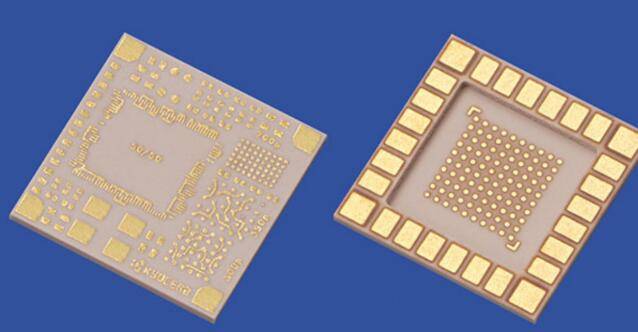

精密セラミック部品は、その卓越した機械的特性と過酷な条件下での弾力性により、様々な最先端技術において極めて重要な役割を果たしています。集積回路製造の領域では 集積回路製造 半導体デバイスに要求される高精度と信頼性を維持するために不可欠な部品です。その高い強度と硬度により、性能を損なうことなく製造工程の厳しい要求に耐えることができます。

レーザー レーザー技術 精密セラミックスは、高エネルギーのレーザー照射下で構造的完全性を維持する能力により利用されています。熱衝撃に対する耐性と光学的透明性により、医療用レーザーや工業用切削工具など、レーザービームの正確な操作が重要な用途に最適です。

また センシング分野 精密セラミックスの高感度と安定性は、センシング分野で大きな利益をもたらします。これらの部品は、環境監視システムや産業オートメーションに見られるような、正確で信頼性の高いデータ収集が必要なセンサーによく使用されます。その耐久性は、過酷な環境下でも長期的な性能を保証します。

超電導技術 は、精密セラミックスのユニークな特性を活用して高温超電導を実現します。これらの材料は、低電気抵抗と高電流密度を必要とする超電導磁石やその他の部品の開発に不可欠です。従来の超電導体よりも高温で動作するその能力は、エネルギー効率の高い技術に新たな可能性を開きます。

バイオ バイオメディカル用途 精密セラミックスは、生体適合性と機械的強度が高く評価されています。人体とシームレスに統合する必要のあるインプラントや人工装具に使用されています。腐食や摩耗に対する耐性があるため、これらの医療機器は長期間にわたって効果を維持し、患者の転帰を改善し、頻繁な交換の必要性を低減します。

全体として、精密セラミック部品の多用途性と堅牢性は、複数の技術領域にわたって不可欠なものとなっており、技術革新を推進し、重要なシステムの性能を高めています。

課題と限界

精密セラミックは、高強度や極限環境に対する耐性など数多くの利点を提供する一方で、その製造と使用を複雑にする重大な課題を抱えています。主な問題の1つは、固有の高い硬度と脆さであり、機械加工が難しいことで有名です。この特性は、製造工程の複雑さを増すだけでなく、機械的応力下で材料に亀裂や破壊が生じやすくなります。

精密セラミックスは脆いため、特殊な機械加工技術を使用する必要があり、多くの場合、高い運用コストがかかります。例えば、従来の切削方法は、材料が変形しにくいため効果的ではなく、切削工具の摩耗の増加やエネルギー消費の増加につながります。さらに、機械加工中にマイクロクラックが発生するリスクは、最終製品の全体的な品質と性能を低下させ、生産コストをさらにエスカレートさせる。

さらに、これらのセラミックは硬度が高いため、柔軟性と成形のしやすさが求められる特定の場面での適用が制限される可能性があります。また、この剛性は、動的条件への適応性と回復力を必要とするシステムに精密セラミック部品を組み込む際の課題となる可能性があります。

要約すると、精密セラミックはその性能特性から非常に望ましいものですが、その高い硬度と脆性は、コストの増加や製品欠陥の可能性など、製造上の大きな障害となります。これらの課題に対処するには、革新的な加工技術と、性能と製造性のバランスを最適化するための慎重な材料選択が必要です。

精密セラミックスの準備技術

射出成形

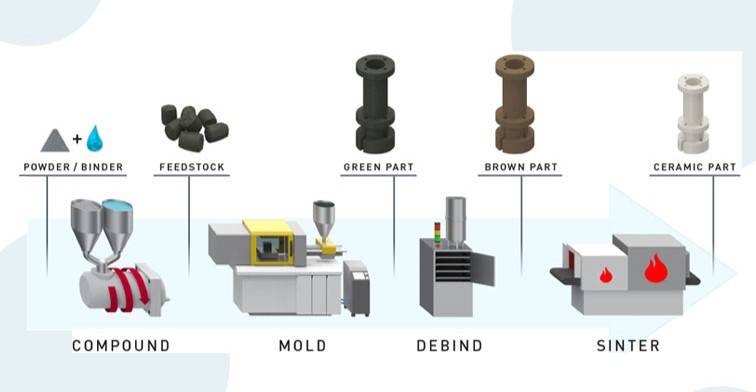

セラミック射出成形 (CIM) は、伝統的なポリマー射出技術と高度なセラミック調製法を融合させた高度なプロセスです。この革新的なアプローチにより、卓越した寸法精度と均一な密度を備えた、複雑で小規模なセラミック部品の作成が可能になります。このプロセスは、まず微細なセラミック粉末をポリマーバインダーとブレンドし、これを高圧下で金型に注入します。部品が成形されると、脱バインダー工程でバインダーが除去され、続いて焼結が行われ、最終的なセラミック構造が完成します。

CIMの主な利点の一つは、従来のセラミック成形法では困難または不可能な複雑な形状を製造できることである。この能力は、航空宇宙、医療機器、電子機器など、高性能で精密に設計された部品が最も要求される産業で特に価値があります。CIMによって達成される密度の均一性は、部品全体にわたって一貫した機械的特性を保証し、これは信頼性と耐久性を必要とする用途にとって極めて重要です。

さらに、CIMは従来のセラミック製造方法に比べて大幅なコスト削減と効率向上を実現します。ネットシェイプに近い部品の製造を可能にすることで、CIMは大規模な後処理の必要性を減らし、それによって材料の無駄と製造時間を削減します。この効率は、射出成形工程を自動化できることでさらに向上し、安定した品質と人件費の削減につながります。

まとめると、セラミック射出成形は、ポリマー加工とセラミック工学のギャップを埋める最先端技術であり、卓越した性能特性を持つ高精度のセラミック部品を生産するための多用途のソリューションを提供します。

射出ゲル成形

射出ゲル成形は、伝統的なセラミック成形技術と高度な有機重合法をシームレスに統合することで、セラミック製造における重要な進歩を象徴しています。この革新的なプロセスは、大型で複雑なセラミック部品の製造に不可欠な、ネットサイズに近い高強度セラミックブランクの製造に特に有利です。所望の形状や強度を得るために大規模な後処理を必要とすることが多い従来の方法とは異なり、射出ゲル成形では成形サイクル時間が大幅に短縮されるため、生産効率が向上します。

このプロセスは、セラミック材料とポリマー材料の両方の長所を生かし、従来の方法では困難であった複雑な形状の成形を可能にします。これらの技術を組み合わせることで、メーカーは均一な密度と優れた機械的特性を持つセラミック部品を製造することができ、高精度と耐久性を必要とする用途に最適です。この方法は、製造工程を合理化するだけでなく、材料の無駄を最小限に抑え、より持続可能な製造環境に貢献します。

まとめると、射出ゲル成形は、従来のセラミック成形の限界に対処する最先端技術であり、複雑な形状で成形サイクルが短い高性能セラミック部品の製造に汎用性の高いソリューションを提供します。

3Dプリンティング成形

3Dプリンティングは、前例のないスピードと効率で非常に複雑な部品の作成を可能にすることで、精密セラミックの製造に革命をもたらします。従来の成形方法とは異なり、3Dプリンティングは、高度なコンピュータ支援設計(CAD)と製造プロセスを統合し、金型を使用せずに材料を層ごとに堆積させることができます。この方法は、従来の技術では困難または不可能な複雑なセラミック部品の製造に特に有利です。

3Dプリンティングの柔軟性は、幅広いセラミック材料に及んでおり、それぞれが特定の用途に利用できるユニークな特性を持っています。例えば、ジルコニア、アルミナ、窒化ケイ素は、高い強度と過酷な条件への耐性を持つため、3Dプリンティングで一般的に使用されています。これらの材料を複雑な形状でプリントできるため、最終製品は正確な寸法要件と性能基準を満たすことができます。

さらに、3Dプリンティングでは、複数のツールのセットアップや中間ステップが不要になるため、製造に必要な時間が大幅に短縮されます。この合理化されたプロセスにより、生産が加速されるだけでなく、廃棄物も最小限に抑えられ、環境に優しい選択肢となります。以下の表は、セラミック製造における3Dプリンティングの主な利点を示しています:

| 利点 | 利点 |

|---|---|

| 高い複雑性 | 金型では困難な複雑な形状を作成できる。 |

| 製造時間の短縮 | 複数の金型セットアップや中間工程が不要。 |

| 材料の柔軟性 | 独自の特性を持つさまざまなセラミック材料をサポートします。 |

| 廃棄物の最小化 | 合理化されたプロセスにより、材料の無駄が削減され、効率が向上します。 |

まとめると、3Dプリンティングは、精密セラミックの分野で変革をもたらす技術として際立っており、複雑さ、速度、材料の多様性の面で比類のない能力を提供します。その製造プロセスへの統合は、様々な産業における革新的なソリューションと性能向上の道を開きます。

精密セラミックスの加工技術

化学機械研磨(CMP)

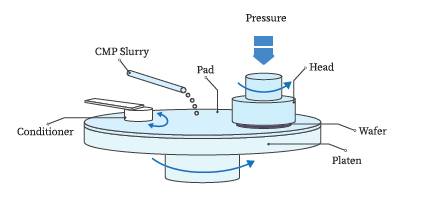

化学的機械研磨(CMP)は、半導体産業において重要なプロセスであり、主にグローバルな平坦化を達成するために利用される。この技術では、ナノスケールの研磨粒子を使用し、高温高圧の条件下で、新しく柔らかい物質を作り出します。この柔らかい物質は除去を容易にし、半導体デバイスの精密な製造に不可欠な超平滑表面をもたらす。

CMPのプロセスは高度に洗練されており、化学的および機械的な力が複雑に絡み合っている。多くの場合、シリカやアルミナのような材料で構成される研磨粒子は、化学薬品も含むスラリーに懸濁されます。これらの薬剤は研磨材の表面と反応し、機械的摩耗を受けやすい薄い層を作ります。化学反応と機械的摩耗の組み合わせにより、材料が均一に除去され、平坦な表面が得られます。

CMPの主な利点のひとつは、多層半導体デバイスの製造に不可欠なグローバルな平坦化を実現できることです。平坦化なしでは、表面の凹凸が後続層の欠陥につながり、デバイス全体の性能や信頼性に影響を及ぼす可能性があります。また、CMPの超平滑な表面を作り出す能力は、欠陥の可能性を低減し、半導体部品の歩留まりと品質を向上させます。

半導体製造に加え、CMPは精密セラミック部品の製造にも応用されている。この技術は、下地の構造に大きなダメージを与えることなく材料を正確に除去できるため、硬くて脆い材料に特に有効です。このためCMPは、航空宇宙、自動車、医療機器など、さまざまな産業で使用される高性能セラミック部品の製造において、非常に貴重なツールとなっている。

しかし、CMPのプロセスに課題がないわけではありません。高温と高圧が要求されるため、装置の摩耗や破損につながり、メンテナンスコストが増加する可能性があります。さらに、材料に過度の損傷を与えることなく効果的な研磨を行うには、スラリー中の研磨粒子と化学薬剤の選択を慎重に最適化する必要があります。このような課題にもかかわらず、高品質かつ超平滑な表面を実現するCMPの利点により、精密セラミックスの分野では不可欠な技術となっています。

磁気レオロジー研磨

磁気レオロジー研磨(MRP)は、精密セラミックスの分野において、比類のない精度と効率を提供する最先端の方法として際立っています。従来の琢磨技術とは異なり、MRPは磁気レオロジー流体-磁場の影響を受けてレオロジー特性が変化するスマートな材料-を活用します。このユニークな特性により、琢磨工程をリアルタイムで調整することが可能になり、高い精度と一貫性が保証されます。

MRPの最も大きな利点の一つは、工具の摩耗がないことです。従来の琢磨方法では、工具の劣化に悩まされることが多く、表面仕上げにばらつきが生じたり、工具の頻繁な交換が必要になったりする。対照的に、MRPでは磁気レオロジー流体を使用するため、この問題が発生せず、プロセス全体を通じて安定した研磨速度と一貫した表面品質を維持することができます。

しかし、MRPの適用に課題がないわけではない。このプロセスでは、入念な準備と高度な装置が要求されるため、必然的にコストが上昇する。MRPシステムのセットアップと運用の複雑さは、特殊な材料と機械に関連する高コストと相まって、産業現場での普及を制限している。MRPは精密研磨に革命をもたらす可能性があるにもかかわらず、参入障壁が高いため工業的規模が制限され、大規模生産よりもニッチで高精度な用途に適しています。

まとめると、MRPは卓越した精度、効率、および工具寿命を提供する一方で、その工業的応用は、高いコストと複雑な準備が必要であるという制約がある。MRPをより利用しやすく、費用対効果の高いものにするためには、技術とプロセスの最適化における将来の進歩が不可欠であり、それによって精密セラミックス産業におけるMRPの適用範囲を広げることができる。

ELID研磨

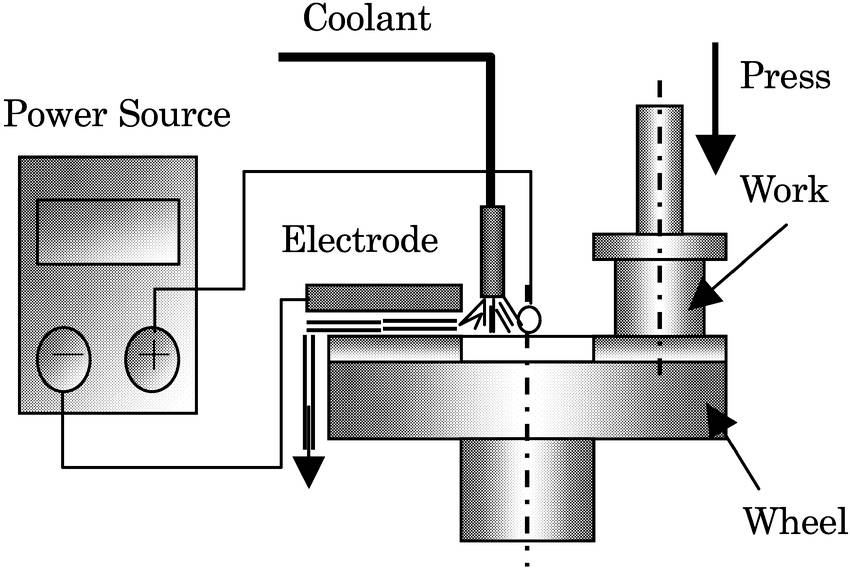

ELID (Electrolytic In-process Dressing) 研削は、従来のチッピング、研削、研磨技術を統合した革新的な複合鏡加工技術である。この方法は、弱電解質を含む水溶液を使用し、セラミック材料の精密加工において重要な役割を果たします。その実施に伴う課題はあるものの、ELID研削は精密セラミックス加工の未来に大きな期待を寄せている。

主な特徴と利点

-

統合加工:ELID研削は、チッピング、研削、研磨を含む複数の従来の機械加工工程を、一つのまとまった方法に統合します。この統合により、製造工程が合理化され、別工程の必要性が減り、製造コストが下がる可能性があります。

-

電解ソリューション:弱電解質の水溶液を使用することが、ELID研削の特徴です。この水溶液は、材料の正確な除去を容易にし、最終製品の精度と平滑性を高めます。また、電解プロセスは、高品質の結果を得るために不可欠な研削工具の切れ味を維持するのにも役立ちます。

-

精密セラミックへの適合性:精密セラミックスは硬度が高く脆いため、従来の加工方法では要求される精度と表面品質が得られないことがよくあります。これらの課題に対応できるELID研削は、精密セラミック部品の加工に特に適しています。

課題と考察

ELID研削にはいくつかの利点がありますが、課題がないわけではありません。電解プロセスが複雑で、電解液の精密な制御が必要なため、大規模な実施は困難です。さらに、初期設定コストが高く、特殊な装置を必要とするため、普及の障壁となる可能性がある。

このような課題にもかかわらず、ELID研削は精密セラミックスの将来にとって有望な技術であり続けています。合理化されたプロセスで高品質な結果をもたらすその能力は、より効率的で効果的なセラミック加工法を追求し続ける上で、貴重なツールとなっている。

まとめると、ELID研削は、精密セラミック加工分野における重要な進歩であり、これらの材料がもたらす特有の課題に対処するために、伝統的な技術と革新的な技術の組み合わせを提供するものである。

レーザー加工

レーザー加工は、非接触で工具を使用しない方法として際立っており、特に脆く硬いセラミック材料に有利な比類のない精度を提供します。この技術は、集光されたレーザービームの力を利用して、マイクロスケールやナノスケールで材料を操作するため、従来の機械加工法では困難な複雑な作業に最適です。

しかし、レーザー加工は精度に優れている反面、課題がないわけではない。一貫した精度を確保し、高い表面品質を維持することは、難しいことです。レーザー加工の性質上、レーザー出力、パルス時間、ビーム焦点などのパラメーターを綿密に制御する必要があり、それぞれが最終製品の品質に大きな影響を与える。さらに、非接触で加工を行うため、リアルタイムでのモニタリングや偏差の修正は複雑なものとなります。

このような課題にもかかわらず、レーザー加工は精密セラミック製造の要であり続けています。複雑な形状と高い寸法精度を達成するその能力は、従来の方法では不十分な用途に不可欠です。研究と技術が進歩し続けるにつれて、レーザー加工の精度と表面品質管理は向上し、精密セラミック製造の将来におけるその役割はさらに確固たるものになると期待されています。

プラズマアシスト研磨

プラズマ支援琢磨は、セラミック表面仕上げへの新しいアプローチであり、プラズマのユニークな特性を活用して精密な材料除去を実現します。従来の湿式琢磨法とは異なり、この技術は乾燥環境で作動するため、流体の取り扱いと廃棄に関する問題が軽減されます。高エネルギーと反応種を特徴とするプラズマ照射は、材料表面の選択的エッチングを可能にし、超平滑仕上げの達成を容易にする。

しかし、プラズマアシスト研磨の採用にはハードルがないわけではない。主な課題の1つは、従来技術に比べて材料除去率が相対的に低いことです。この制限により、処理時間が長くなり、高スループットの製造環境では大きな欠点となります。さらに、プラズマアシスト琢磨に必要な特殊な装置は法外に高価であることが多く、産業界に広く導入するには経済的な障壁となる。このような課題にもかかわらず、現在進行中の研究は、プラズマ・パラメーターを最適化してプロセスの効率を高め、精密セラミックスの領域でその可能性を最大限に引き出すことを目指しています。

複合研磨プロセス

複合研磨プロセスは、精密セラミックスの分野における重要な進歩であり、表面品質と加工効率の両方を向上させる相乗的なアプローチを提供します。超音波振動アシスト研磨や化学機械研磨(CMP)など、さまざまな技術を融合させることで、優れた結果を得ることができます。

超音波振動アシスト研削は、研削プロセスに高周波振動を導入することで、工具摩耗を大幅に低減し、材料除去率を向上させることができます。この方法は、従来の研削方法では効率が悪く、表面欠陥が発生しやすい、精密セラミックのような硬くて脆い材料に特に効果的です。

一方、化学機械研磨(CMP)は半導体産業で確立された技術であり、ナノスケールの砥粒と化学反応の相互作用によって超平滑な表面を作り出す能力で知られています。CMPを超音波研削と組み合わせることで、表面仕上げをさらに洗練させることができ、集積回路や光学部品など、高精度が要求される用途に不可欠なレベルの平滑性を達成することができます。

これらの手法を組み合わせることで、全体的な表面品質が向上するだけでなく、加工効率も向上します。各技術の長所を活用することで、複合琢磨工程は、精密セラミックの高品質表面の実現に関連する時間とコストを削減することができます。この統合的アプローチは、複雑な形状と完璧な仕上げの両方を必要とする複雑なセラミック部品に特に有益です。

まとめると、複合研磨プロセスは、精密セラミックスの分野で採用されている革新的な戦略の証であり、異なる技術を組み合わせることで、品質と効率の両面でいかに優れた結果を導き出せるかを実証している。

結論と今後の動向

開発動向

精密セラミック部品の準備における機械加工の削減は、ハイテク技術の進歩を活用したニアネットフォーミング技術の統合によって推進される重要な傾向です。これらの技術は、高精度の形状と高い寸法精度を実現し、加工後の機械加工の必要性を最小限に抑えるように設計されている。

主なニアネットフォーミング技術

| 技術名 | 技術概要 | 利点 |

|---|---|---|

| 射出成形 | ポリマー射出成形法とセラミック前処理工程を組み合わせます。 | 均一な密度を持つ小型で複雑な部品の製造が可能。 |

| 射出ゲル成形 | 従来のセラミック成形と有機重合法を統合。 | 複雑な形状のニアネットサイズの高強度セラミックブランクを製造します。 |

| 3Dプリンティング | コンピューター支援設計および製造を利用して、層ごとに積層します。 | 金型を必要としない非常に複雑なセラミック部品に適しています。 |

これらのニアネットフォーミング技術は、セラミック部品の精度を高めるだけでなく、製造工程を合理化し、コスト削減と効率向上を実現します。大規模な機械加工の必要性を最小限に抑えることで、これらの方法は、従来の機械加工プロセスで一般的な課題である、セラミックの脆性や硬度に関する問題を軽減するのに役立つ。

集積回路製造、レーザー技術、生物医学用途など、さまざまなハイテク産業における精密セラミック部品の需要の増加を背景に、こうした先端技術の採用は今後も拡大すると予想される。

研究開発ニーズ

精密セラミックスの進歩は、特に大型で複雑な構造の領域において、いくつかの根強い課題によって妨げられています。これらの課題は、以下のような様々な形で現れています。 低い歩留まり率 , 複雑な成形工程 そして 生産コストの上昇 .これらの問題に対処するには、研究開発(R&D)において、現在の手法を革新し、最適化するための協調的な努力が必要である。

主なハードルの一つは 歩留まりの低さ です。従来の成形技術では、均一性と構造的完全性を維持するのに苦労することが多く、大幅な材料廃棄とコスト増につながります。そのため、次のような新しい成形技術の探求が必要となっている。 3Dプリンティング のような新しい成形技術の探求が必要となっている。

成形工程の複雑さ 成形工程の複雑さ は、こうした課題をさらに悪化させる。セラミック射出成形(CIM)や射出ゲル成形は、小さな部品には効果的ですが、より大きく複雑な設計に適用する場合、拡張性の問題に直面します。これらの制約を克服するためには、より汎用的で拡張性のある成形技術の開発が不可欠である。例えば 複合研磨プロセス を従来の方法と統合することで、大規模生産の精度と効率を高めることができる。

さらに 高コスト が普及の大きな障壁となっています。これらのコストは、特殊な装置、熟練した労働力、および大規模な後処理の必要性によってもたらされています。これを軽減するために、費用対効果の高い代替案とプロセスの最適化が急務となっている。以下のような技術 ELID研削 や プラズマアシスト研磨 のような技術は、高品質基準を維持しながらコストを削減する上で有望である。

まとめると、現在進行中の研究開発努力は、歩留まり率の向上、複雑な成形工程の簡素化、生産コストの削減に焦点を当てる必要があります。新たな技術を活用し、高度な手法を統合することで、精密セラミックスの分野はこれらの課題を克服し、より広範な産業応用への道を開くことができます。

おすすめの記事

https://www.allowtex.co.jp/blog/detail/fq54jUOK

関連製品

- カスタムPTFEテフロン部品、熱水合成反応器用ポリテトラフルオロエチレンカーボン紙およびカーボンクロスナノ成長メーカー

- PTFEボールバルブシート用カスタムPTFEテフロン部品メーカー

- エンジニアリング先進ファインセラミックス用高温アルミナ(Al2O3)炉心管

- 培養皿・蒸発皿用カスタムPTFEテフロン部品メーカー

- 非標準絶縁体のカスタマイズのためのカスタムPTFEテフロン部品メーカー