本質的に、プラズマ支援化学気相成長法(PECVD)は、ガス状態から基板上に薄膜を堆積させるために使用されるプロセスです。従来の化学気相成長法(CVD)が化学反応を促進するために高温に依存するのに対し、PECVDはプラズマのエネルギーを利用して、はるかに低い温度でこれらの反応を開始させます。これにより、熱に敏感な材料を含む、より幅広い材料のコーティングが可能になります。

PECVDの主な利点は、高温の熱エネルギーの代わりにプラズマエネルギーを使用できることです。この根本的な違いにより、他の方法では損傷してしまう温度に敏感な材料上に、高品質で機能的な薄膜を作成する能力が解き放たれます。

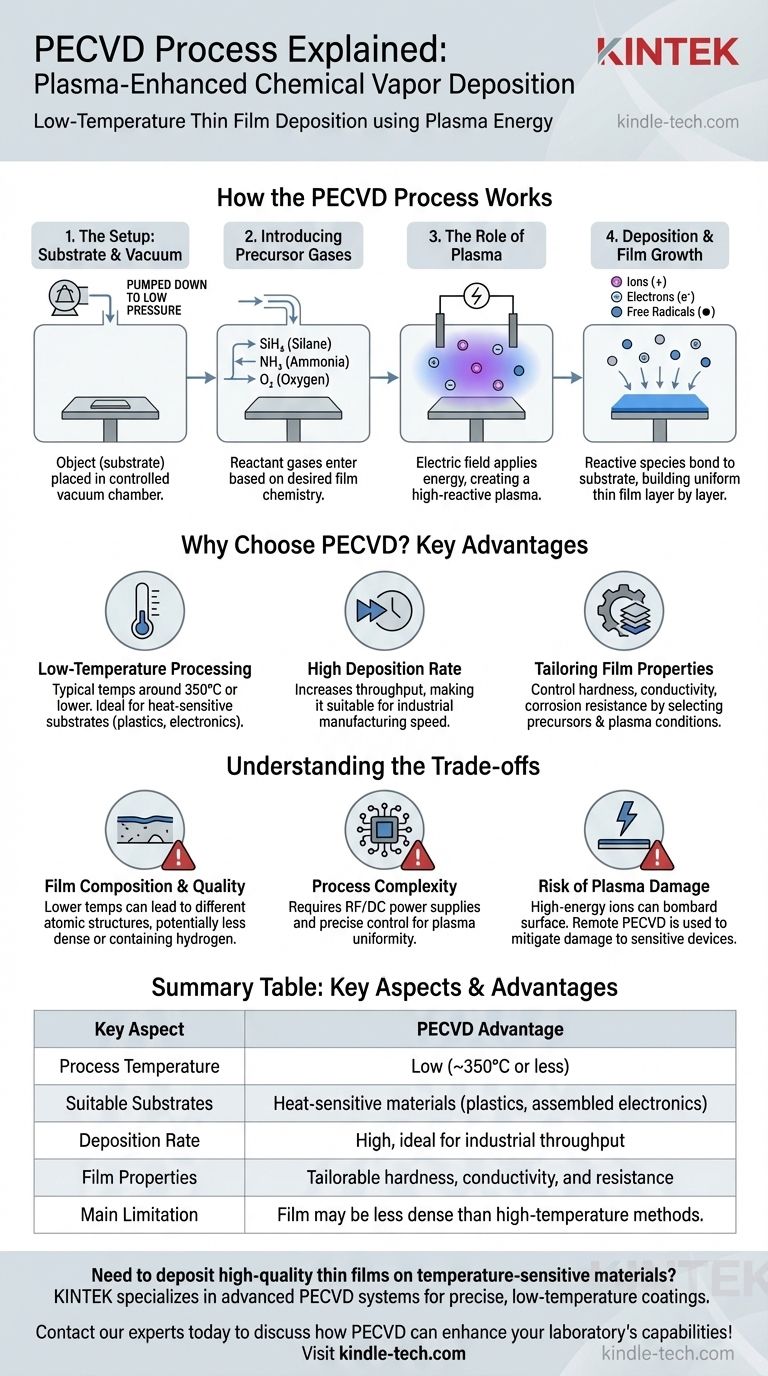

PECVDプロセスの仕組み

PECVDを理解するには、その構成要素のステップに分解するのが最善です。プロセス全体は、純度とプロセスの安定性を確保するために、制御された真空チャンバー内で行われます。

セットアップ:基板と真空

まず、コーティングされる対象物(基板と呼ばれる)が反応チャンバー内に配置されます。次に、チャンバーは低圧まで排気され、汚染物質を除去する真空状態が作られます。

前駆体ガスの導入

反応ガス、別名前駆体(プリカーサー)がチャンバーに導入されます。最終的な膜の望ましい特性に基づいて、特定のガス化学が選択されます。例えば、二酸化ケイ素膜や窒化ケイ素膜を作成するために、ケイ素を含むガスが使用されます。

プラズマの役割

これがPECVDを決定づけるステップです。チャンバー内の電極間に電場が印加され、前駆体ガスが点火され、それらがプラズマに変換されます。これはしばしば特徴的なグロー放電として見られます。

このプラズマは、ガス分子がイオン、電子、および非常に反応性の高いフリーラジカルの混合物に分解された高エネルギー状態の物質です。このエネルギーが、極度の熱を必要としない化学反応を促進するものです。

堆積と膜の成長

プラズマ内で生成された反応性の化学種は、次に基板に向かって拡散します。より冷たい基板の表面に到達すると、それらは反応して結合し、固体で薄い膜を堆積させます。このプロセスは層ごとに積み重なり、慎重に制御された厚さと特性を持つ均一なコーティングを形成します。

なぜPECVDを選ぶのか?

PECVDは単なるいくつかの選択肢の一つではなく、他の方法では容易に対処できない特定のエンジニアリング上の課題を解決します。

低温の利点

最も重要な利点は、低いプロセス温度であり、通常は約350°C以下です。従来のCVDは600〜800°Cを超える温度を必要とすることがあります。これにより、PECVDはプラスチック、組み立て済みの電子デバイス、および高温に耐えられないその他の基板のコーティングに理想的です。

高い堆積速度

低温技術である低圧CVD(LPCVD)などと比較して、PECVDはしばしば高い堆積速度を持ちます。これによりスループットが向上し、速度が重要な要素となる産業製造において非常に価値があります。

膜特性の調整

最終的な膜の特性は、前駆体ガスとプラズマ条件に直接関連しています。前駆体を慎重に選択することにより、エンジニアは特定の用途に合わせて、膜の硬度、電気伝導性、耐食性、または光学特性などの膜特性を調整できます。

トレードオフの理解

完璧なプロセスはありません。信頼できるアドバイザーであるためには、技術の限界と潜在的な欠点を認識する必要があります。

膜の組成と品質

PECVDは低温で動作するため、得られる膜は高温プロセスによる膜とは異なる原子構造を持つことがあります。密度が低かったり、前駆体ガス由来の水素などの元素が取り込まれていたりする可能性があります。これは必ずしも欠点ではありませんが、重要な設計上の考慮事項です。

プロセスの複雑さ

プラズマを生成および維持するためにRFまたはDC電源を使用することは、装置とプロセス制御に複雑さを一層加えます。プラズマの均一性を管理することは、基板全体に一貫したコーティングを達成するために極めて重要です。

プラズマ損傷のリスク

構成によっては、プラズマ内の高エネルギーイオンが基板表面を物理的に衝突することがあります。これは膜の密着性に有益な場合もありますが、敏感な電子デバイスに損傷を与える可能性もあります。このリスクを軽減するために、プラズマを基板から離れた場所で生成するリモートPECVDなどの高度な技術が開発されました。

目標に合った正しい選択をする

堆積方法の選択は、プロジェクトの制約と望ましい結果に完全に依存します。

- 熱に弱い基板のコーティングが主な焦点である場合: PECVDは、その根本的に低いプロセス温度により、しばしばデフォルトであり、優れた選択肢となります。

- 可能な限り最高の膜純度と密度を達成することが主な焦点である場合: LPCVDなどの高温プロセスを評価する必要があるかもしれませんが、それを基板の熱的限界と天秤にかける必要があります。

- 堅牢な材料に対する迅速な生産スループットが主な焦点である場合: PECVDの高い堆積速度は、産業規模のアプリケーションにとって非常に有力な候補となります。

その中核的なメカニズムとトレードオフを理解することで、PECVDを効果的に活用し、特定の機能のために材料表面を設計することができます。

要約表:

| 主要な側面 | PECVDの利点 |

|---|---|

| プロセス温度 | 低い(約350°C以下) |

| 適切な基板 | 熱に弱い材料(プラスチック、組み立て済み電子機器) |

| 堆積速度 | 高い、産業用スループットに理想的 |

| 膜特性 | 調整可能な硬度、導電性、耐性 |

| 主な制限 | 高温プロセスによる膜よりも密度が低い可能性がある |

熱に弱い材料上に高品質の薄膜を堆積させる必要がありますか? KINTEKは、研究や生産のニーズに合わせて正確な低温コーティングを実現するために、PECVDシステムを含む高度なラボ機器を専門としています。当社の専門知識により、プラスチック、電子機器、その他のデリケートな基板のコーティングに関して、適切なソリューションを得ることができます。当社の専門家に今すぐお問い合わせいただき、PECVDがお客様のラボの能力をどのように向上させられるかをご相談ください!

ビジュアルガイド

関連製品

- 傾斜回転プラズマエッチングCVD(PECVD)装置 チューブ炉 マシン

- ラミネート・加熱用真空熱プレス機

- 915MHz MPCVDダイヤモンドマシン マイクロ波プラズマ化学気相成長装置 リアクター

- 伸線ダイス用ナノダイヤモンドコーティングHFCVD装置

- 1700℃実験室用高温管状炉(アルミナチューブ付き)

よくある質問

- PECVD装置はどのようにしてカーボンナノチューブの方向性成長を促進しますか?精密な垂直配向を実現する

- プラズマ層成膜プロセスとは?高性能コーティング技術ガイド

- PECVDコーティングとは?エレクトロニクスおよび熱に敏感な材料のための低温プロセス

- PECVDにおけるプラズマの役割とは?低温で高品質な薄膜成膜を実現

- LPCVD酸化膜とPECVD酸化膜の違いは何ですか?熱バジェットに合わせた適切な成膜方法の選択

- プラズマCVDは金属を堆積できますか?PECVDが金属堆積にほとんど使用されないのはなぜですか?

- 太陽電池におけるPECVDとは?高効率な反射防止とパッシベーションの鍵

- DLCコーティングはどのくらい持続しますか?コンポーネントの究極の耐久性を解き放つ