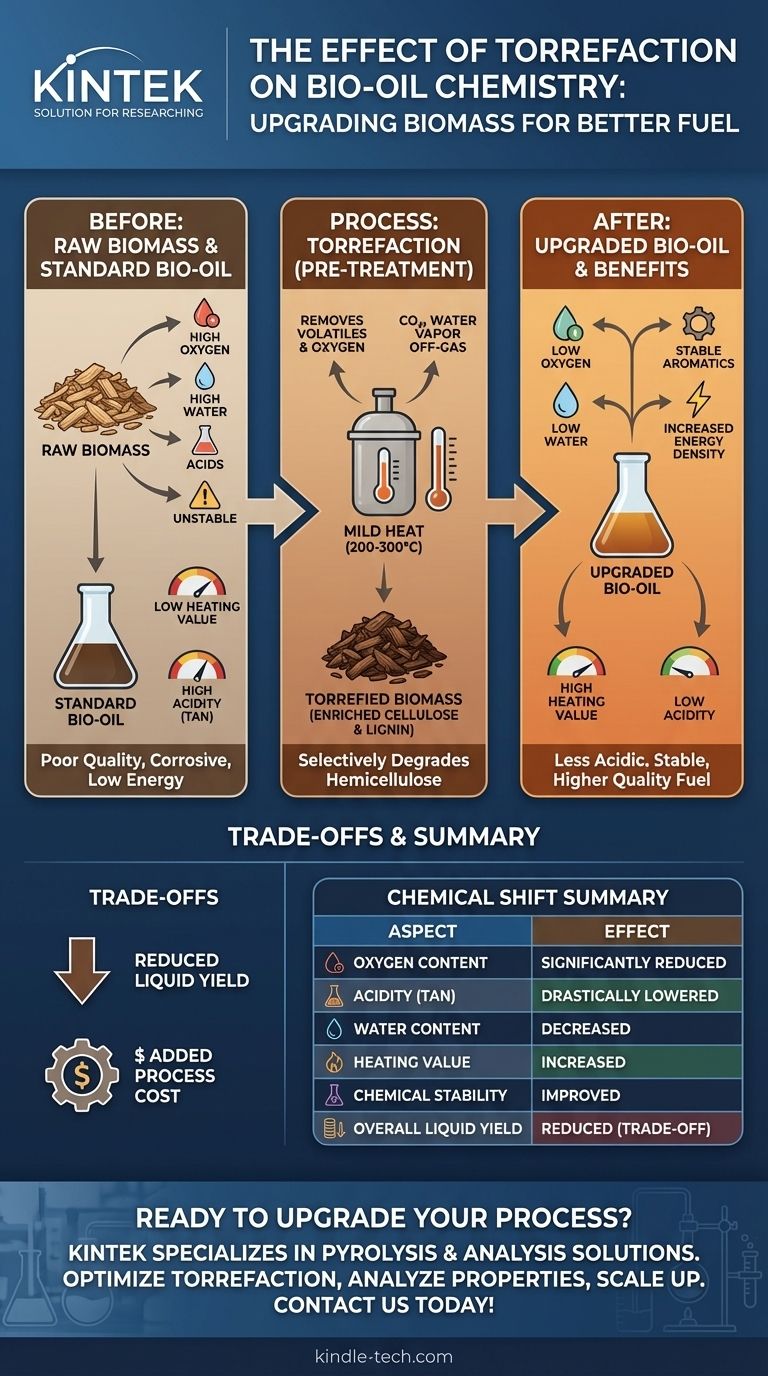

乾留処理は、バイオオイル中の酸素含有量を削減し、安定した高エネルギー密度化合物の濃度を高めることにより、高速熱分解バイオオイルの化学組成を根本的に変化させます。 この前処理工程では、初期バイオマスを不活性雰囲気下で焙焼し、熱分解炉に入る前に最も反応性が高く酸素を多く含む成分を分解します。その結果、得られるバイオオイルは酸性度が低く、水分が少なく、発熱量が高くなり、燃料としての利用を制限していた品質上の主要な問題に直接対処します。

標準的なバイオオイルの中心的な課題は、高い酸性度と低いエネルギー密度によって引き起こされる品質の低さです。乾留は、バイオマス自体をアップグレードするための戦略的な前処理であり、従来の燃料油により近い、より高品質で安定したバイオオイルの直接的な生産につながります。

なぜバイオオイルの品質が問題なのか

乾留処理の影響を理解するためには、まず未処理バイオマスから生成されたバイオオイルの固有の化学的限界を認識する必要があります。これらの問題は、植物物質自体の化学組成に直接起因しています。

高い酸素と水分の含有量

未処理バイオマスには、その分子構造内にかなりの量の酸素が含まれています。高速熱分解中、この酸素は主に水、酸、アルデヒド、ケトンなどの形でバイオオイルに持ち越されます。この高い酸素含有量が、バイオオイルの発熱量が低い主な理由であり、石油燃料の半分程度であることがよくあります。

固有の酸性度と腐食性

バイオマスの主要成分であるヘミセルロースの分解により、特に酢酸やギ酸などのカルボン酸が大量に生成されます。これらの酸によりバイオオイルは標準的な鋼管やエンジンに対して非常に腐食性が高くなるため、取り扱いや保管には高価な特殊材料が必要になります。

化学的不安定性

バイオオイルは、アルデヒドやケトンなどの反応性の高い化合物を含む複雑な混合物です。時間の経過とともに、これらの分子は互いに反応し、より大きなポリマーを形成します。この経時変化の過程でバイオオイルの粘度が増加し、ポンプで送ったり使用したりすることが困難になります。

乾留処理が原料をアップグレードする方法

乾留処理は、熱分解を受ける前にバイオマスの性質を根本的に変える穏やかな熱処理(200~300°C)です。これが最終製品を改善するための鍵となります。

ヘミセルロースの選択的分解

ヘミセルロースはバイオマスの中で最も不安定なポリマーであり、結果として生じるバイオオイル中の酸と水の主な供給源です。乾留処理はこの成分を選択的に標的として分解し、その揮発性で酸素を多く含む要素をガス(CO2など)や水蒸気として放出させます。

リグニンとセルロースの濃縮

ヘミセルロースの最も反応性の高い部分を除去することにより、残りの固形バイオマスはセルロースとリグニンで濃縮されます。これらの成分はエネルギー密度が高く、熱分解中に腐食性の酸よりも価値のある芳香族化合物やフェノール化合物を生成する傾向があります。

バイオオイルにおける結果的な化学的変化

この乾留処理されアップグレードされたバイオマスを熱分解炉に供給すると、生成されるバイオオイルの化学的プロファイルが劇的に改善されます。

酸性度の劇的な低減

ヘミセルロースの前駆体がすでに除去されているため、熱分解中の酢酸やギ酸の生成が大幅に抑制されます。これによりバイオオイルの総酸価(TAN)が直接低下し、腐食性が大幅に低減されます。

水分の低減

乾留処理工程では、バイオマス中の遊離水と、熱分解中に水が生成されたであろう酸素含有官能基の両方が除去されます。最終的なバイオオイル中の水分含有量が低いことは、発熱量が高いことに直接つながります。

芳香族化合物の増加

リグニンが豊富な原料の熱分解は、より安定したフェノール性化合物や芳香族化合物の高い割合をもたらします。これらの分子は時間の経過とともに安定しているだけでなく、バイオオイルの発熱量にも大きく貢献します。これにより、液体燃料の全体的な安定性と品質が向上します。

トレードオフの理解

乾留処理は大きな化学的利点をもたらしますが、課題がないわけではありません。客観的な評価を行うには、欠点を認識する必要があります。

液体収率の全体的な低下

主なトレードオフは、*未処理*バイオマス1トンあたりのバイオオイルの総生産量が減少することです。乾留処理工程は、そうでなければ液体製品の一部になったであろう揮発性物質を放出させます。より高品質のオイルは得られますが、その量は少なくなる可能性があります。

プロセスの複雑さとコストの増加

乾留処理ユニットの統合は、バイオリファイナリーに多大な資本的および運営上の費用を追加します。経済的な実行可能性は、アップグレードされたバイオオイルの市場での価値向上によって、これらの追加コストを相殺できるかどうかにかかっています。

正味エネルギー収支

乾留処理工程自体は、バイオマスを加熱するためにかなりのエネルギー入力を必要とします。乾留中に生成される可燃性ガスで一部のエネルギー需要を相殺できますが、統合プロセスの全体的なエネルギー収支を注意深く分析する必要があります。

目標に応じた適切な選択

乾留処理を使用するかどうかの決定は、最終製品に求められる特性に完全に依存します。

- 主な焦点が液体燃料の最大化である場合: 乾留処理は逆効果になる可能性があります。なぜなら、それは初期の未処理バイオマス1トンあたりのバイオオイル総収量を減少させることが知られているからです。

- 主な焦点が、高品質で安定したドロップイン燃料の生産である場合: 乾留処理は、最終的なバイオオイルの酸性度を低減し、水分含有量を下げ、エネルギー密度を高めるための非常に効果的な前処理です。

- 主な焦点が経済的な実行可能性である場合: 乾留処理ユニットの追加コストと、アップグレードされた腐食性の低いバイオオイルの市場価値の上昇を比較する徹底的な技術経済分析を行う必要があります。

結局のところ、乾留処理は、バイオオイルの「量」と引き換えに、その「品質」の大幅かつ必要な改善を得るための戦略的な手段です。

要約表:

| 側面 | 乾留処理の影響 |

|---|---|

| 酸素含有量 | 大幅に減少 |

| 酸性度(TAN) | 劇的に低下 |

| 水分含有量 | 減少 |

| 発熱量 | 増加 |

| 化学的安定性 | 改善 |

| 全体的な液体収率 | 減少(トレードオフ) |

バイオマス転換プロセスをアップグレードし、より高価値のバイオオイルを生産する準備はできていますか?

KINTEKでは、熱分解およびバイオマス分析のための高度な実験装置を専門としています。当社のソリューションは、研究者やエンジニアが、本記事で概説されている特定の燃料品質と安定性の目標を達成するために、乾留処理などの前処理プロセスを最適化するのに役立ちます。

当社がお手伝いできること:

- 特定のバイオマス原料の乾留処理パラメーターをテストおよび最適化する。

- アップグレードされたバイオオイルの化学的特性を正確に分析する。

- 信頼性の高い機器により、研究室からパイロット、生産へとプロセスをスケールアップする。

当社の実験装置と消耗品に関する専門知識が、お客様のバイオ燃料の研究開発をどのように前進させることができるかについて、今すぐお問い合わせください。今すぐ専門家にご連絡ください!

ビジュアルガイド

関連製品

- 電気ロータリーキルン連続稼働小型ロータリー炉加熱熱分解プラント

- ロータリーチューブファーネス分割マルチ加熱ゾーン回転チューブファーネス

- 真空シール連続稼働ロータリーチューブ炉 回転チューブ炉

- 実験室用ラピッドサーマルプロセス(RTP)石英管炉

- 熱水合成用高圧実験室オートクレーブ反応器