不活性雰囲気は、望ましくない化学反応を防ぐために使用される重要な管理手段です。作業空間内の反応性の高い空気、主に酸素と水蒸気を、非反応性のガスに置き換えることで、材料を劣化から保護し、プロセスの純度を確保し、火災や爆発のリスクを排除します。

私たちの周りの空気は中立ではありません。それは敏感な材料を損傷し、デリケートなプロセスを妨害する可能性のある反応性の化学物質です。不活性雰囲気は保護シールドとして機能し、望ましくない大気干渉のリスクなしに作業を実行できる安定した環境を作り出します。

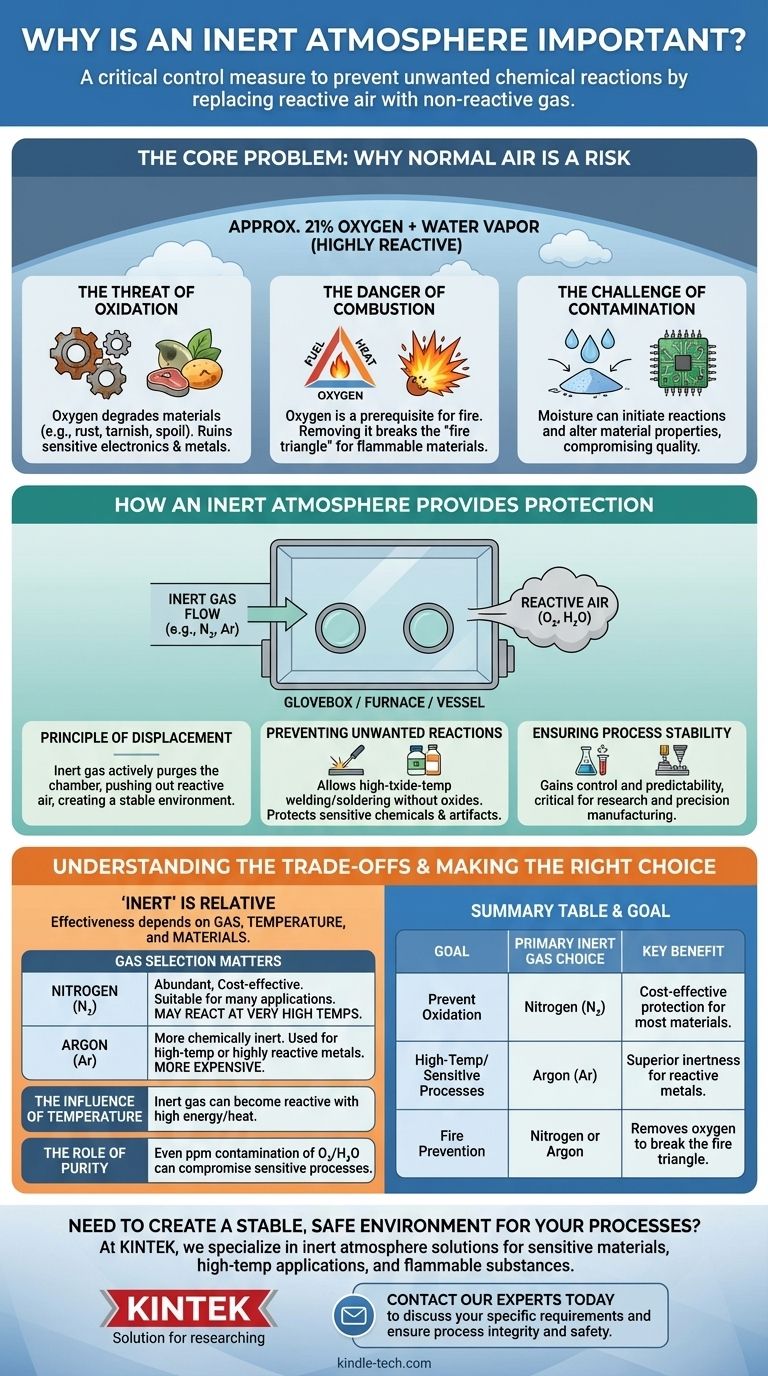

中心的な問題:なぜ通常の空気がリスクなのか

解決策を理解するためには、まず問題点を認識する必要があります。私たちが生活している標準の大気は、約21%の酸素を含み、変動する量の水蒸気を含んでおり、これらは両方とも非常に反応性が高いです。

酸化の脅威

酸素は攻撃的です。それは酸化と呼ばれるプロセスで多くの材料と容易に反応し、それらを劣化させます。

これは、鉄が錆びたり、銅が変色したり、食品が腐敗したりするのと同じ化学反応です。技術的または製造の現場では、酸化は敏感な電子機器を台無しにし、金属を弱め、製品の化学組成を変化させる可能性があります。

燃焼の危険性

酸素の存在は火災の前提条件です。燃焼が発生するためには、燃料、熱、酸化剤(通常は酸素)の3つが必要です。

方程式から酸素を取り除くことで、この「火の三角形」を破壊します。これは、通常の雰囲気中で発火または爆発する可能性のある可燃性の溶剤、微細な金属粉末、またはその他の材料を取り扱う場合に不可欠です。

汚染の課題

酸素以外にも、湿気などの他の大気成分が汚染物質として作用することがあります。水蒸気は望ましくない反応を開始させたり、吸湿性材料に吸収されてその特性を変化させ、最終製品の品質を損なったりする可能性があります。

不活性雰囲気がどのように保護を提供するのか

不活性雰囲気を作り出すことは、グローブボックス、炉、反応容器などの密閉された環境内の周囲の空気を積極的に排除し、内部の材料と反応しないガスに置き換えることを伴います。

置換の原理

基本的なメカニズムは単純です。不活性ガスの一定の流れを使用してチャンバーをパージし、軽くて反応性の高い空気を押し出します。その結果、内部の雰囲気はほぼ完全に安定した非反応性ガスで構成されます。

望ましくない反応の防止

酸素と湿気が除去されると、劣化の主な原因がなくなります。これにより、結合を弱める酸化物の生成なしに、高温溶接やろう付けなどのプロセスが可能になります。また、敏感な化学物質や人工物の長期保管も可能になります。

プロセスの安定性の確保

大気の反応性という変数を排除することで、プロセスに対する制御と予測可能性が向上します。この安定性は、わずかな意図しない反応でさえ失敗につながる可能性のある科学研究や高精度製造において極めて重要です。

トレードオフの理解:「不活性」は相対的である

「不活性」という用語は絶対的ではありません。不活性雰囲気の有効性は、使用される特定のガス、プロセスの温度、および関与する材料に依存します。

ガスの選択が重要

最も一般的な不活性ガスは窒素(N₂)とアルゴン(Ar)です。窒素は豊富で費用対効果が高いため、多くの用途に適しています。ただし、非常に高温では、特定の金属と反応して窒化物を形成する可能性があります。

アルゴンは窒素よりも化学的に不活性であり、窒素が不適切な高温プロセスや非常に反応性の高い金属によく使用されます。ただし、著しく高価です。

温度の影響

室温で不活性であるガスでも、高温などの十分なエネルギーが導入されると反応性になる可能性があります。これが、炉や溶接用途に適切な不活性ガスを選択する際に、材料と温度が重要な要因となる理由です。

純度の役割

不活性ガスの純度は最も重要です。ガス供給源に数ppmの酸素や湿気の汚染があるだけでも、非常に敏感なプロセスを損なうのに十分な場合があります。

目的に合った適切な選択をする

適切な雰囲気制御の選択は、コストと必要な保護レベルのバランスを取りながら、完全に目標に依存します。

- 主な焦点が一般的な酸化防止である場合: 窒素は、多くの材料とプロセスにとって最も実用的で費用対効果の高い選択肢となることがよくあります。

- 主な焦点が高温または非常に敏感な材料である場合: アルゴンは、窒素でさえ反応する可能性がある場合に優れた不活性性を提供し、保護を保証します。

- 主な焦点が安全性と火災防止である場合: 任意の一般的な不活性ガスで酸素を排除することが、燃焼のリスクを排除するための基本的な戦略です。

意図的に雰囲気を制御することにより、作業の完全性、品質、および安全性に対する究極の制御を得ることができます。

要約表:

| 目的 | 主な不活性ガス選択 | 主な利点 |

|---|---|---|

| 酸化の防止 | 窒素(N₂) | ほとんどの材料に対する費用対効果の高い保護 |

| 高温/敏感なプロセス | アルゴン(Ar) | 反応性金属に対する優れた不活性性 |

| 火災防止 | 窒素またはアルゴン | 火の三角形を破壊するために酸素を除去する |

プロセスのために安定した安全な環境を作る必要がありますか?

KINTEKでは、敏感な材料、高温用途、または可燃性の物質を扱うかどうかにかかわらず、効果的な不活性雰囲気ソリューションを実装するための適切なラボ機器と専門知識の提供を専門としています。当社のチームは、酸化、汚染、燃焼のリスクから作業を保護するために最適なシステムを選択するお手伝いをします。

当社の専門家に今すぐお問い合わせいただき、特定の要件についてご相談の上、研究室プロセスの完全性と安全性を確保してください!

ビジュアルガイド

関連製品

- 1400℃ 窒素・不活性ガス雰囲気制御炉

- 1200℃制御雰囲気炉 窒素不活性雰囲気炉

- 1700℃ 真空雰囲気炉 窒素不活性雰囲気炉

- 制御窒素不活性水素雰囲気炉

- 1400℃実験室用高温管状炉(アルミナチューブ付き)