自動加熱ラボプレス

自動実験用熱プレス機

商品番号 : PZAH

価格は以下に基づいて変動します 仕様とカスタマイズ

- 加熱温度

- 300℃ - 800℃

- 圧力範囲

- 0.01-5.0トンから0.01-60トン

- タブレットサイズ

- 120 x 120 mmから500 x 500 mm

配送:

お問い合わせ 配送詳細を確認してください オンタイムディスパッチ保証.

なぜ私たちを選ぶのか

簡単な注文プロセス、高品質な製品、そしてお客様のビジネス成功のための専門サポート。

用途

自動実験用熱プレス機は、精密な材料加工を必要とする多様な産業において不可欠なツールです。自動車分野では、ダッシュボード、ドアパネル、複合ボディ部品などの重要なコンポーネントを熱成形し、構造的完全性を確保しながら軽量化を実現します。実験室では、これらの機械を厳格な材料試験に活用—極端な圧力下での強度評価、物質への高圧影響の分析、分光法(FTIR、XRF)用の標準ペレットの準備を行います。この技術は以下のような分野でも優れています:

- 複合材料製造:航空宇宙グレードの炭素繊維パネルや軽量構造要素の製造。

- エレクトロニクス:マイクロメートル単位の精度でフレキシブル回路のラミネートや熱に敏感なコンポーネントの接合。

- 研究開発:最大800℃の制御された温度で、ポリマー、セラミックス、ナノマテリアルの工業プロセスをシミュレーション。

- 医療機器製造:材料特性を損なうことなく、生体適合性インプラントの滅菌と成形。

カスタマイズ可能な作業スペース(例:120x120mmから500x500mm)とプログラム可能な多段階サイクルにより、これらの機械はプロトタイピングや品質管理のワークフローに適応します。バッテリー電極の圧縮、グラフェン合成、製薬錠剤コーティングなどを扱う実験室は、再現性のある結果を達成するために比類のない汎用性を見出すでしょう。

特徴

KINTEKの自動熱プレスは、最先端のエンジニアリングとユーザー中心のデザインを統合しています:

- 精密制御:

- プレート表面全体で±0.5℃の偏差のPID制御温度均一性。

- 0.01トンから60トンまでスケール可能な0.01トンの油圧精度。

- 高度なインターフェース:

- 圧力/温度グラフのリアルタイム監視のための7インチIPS HDタッチスクリーン。

- Excelベースのプロセス分析とコンプライアンス文書のためのUSBデータエクスポート。

- 安全性と耐久性:

- 自動シャットダウンセンサーと緊急停止ボタンを備えたアクリル製ドア。

- 100,000サイクル以上の定格の銀メッキ電気接点。

- プログラム可能なワークフロー:

- 独立した圧力/温度/冷却プロファイルを持つ18段階シーケンス。

- 材料遷移を制御するための調整可能なランプレート。

- 熱管理:

- デュアルゾーン加熱/冷却プレートと水アシスト急速冷却。

- 500℃動作用の最大16KWの電力オプション。

堅牢な構造はSKD合金プレスプレートと二重ラミネートガイドコラムを備え、高負荷タスク中の変形を最小限に抑えます。PC経由のリモートコントロールは、バッチ処理とデータ比較を可能にし、ISO認定環境に最適です。

利点

KINTEKのソリューションは、効率性と科学的厳密性を融合させることで、従来のプレス機を上回ります:

- コスト削減:

- 自動化により人件費が70%削減され、エネルギー効率の高いヒーターが電力消費を削減します。

- 0.01トンの圧力増分による材料廃棄物の最小化。

- 生産性の向上:

- 18プログラムメモリにより、夜間の無人バッチ処理が可能になります。

- 急速冷却により、パッシブシステムと比較してサイクルタイムが40%短縮されます。

- 妥協のない品質:

- 航空宇宙グレードのプレートにより、±0.5%の温度均一性が保証されます。

- 緊急プロトコルとデュアル保護ドアにより、操作上の危険が排除されます。

- 拡張性:

- モジュラー設計により、作業スペースのアップグレード(120x120mmから500x500mm)をサポートします。

- 220V/110V互換性とCE認定電子機器により、グローバル展開が容易になります。

産業界は、プロトタイピングの加速、不良率の低減、デジタル化されたプロセス追跡可能性を通じて競争優位性を獲得—これにより、ISO検証の迅速化とROIの向上につながります。精度、安全性、スループットを優先する実験室にとって、この機械は基準を設定します。

実験室の能力を向上させる準備はできましたか?カスタマイズされたソリューションデモについては、KINTEKにお問い合わせください!

技術仕様

| パラメータ | 120×120 | 180×180 | 200×200 | 300×300 | 400×400 | 500×500 |

|---|---|---|---|---|---|---|

| 加熱温度/電力 | 室温~300℃/1.6KW 室温~500℃/2KW 室温~800℃/4.5KW |

室温~300℃/2.2KW 室温~500℃/3.4KW 室温~800℃/6KW |

室温~300℃/2.2KW 室温~500℃/3.4KW 室温~800℃/6KW |

室温~300℃/3KW 室温~500℃/4.5KW |

室温~300℃/4KW 室温~500℃/6KW |

室温~300℃/10KW 室温~500℃/16KW |

| 加熱 | (300℃), (500℃), (800℃) | (300℃), (500℃), 6KW (800℃) | 2.2KW (300℃), 3.4KW (500℃), 6KW (800℃) | 3KW (300℃), 4.5KW (500℃) | 4KW (300℃), 6KW (500℃) | 1 |

| 圧力範囲 | 0.01~5.0トン | 0.01~25トン | 0.01~25トン | 0.01~30トン | 0.01~50トン | 0.01~60トン |

| 圧力精度 | 0.01トン | |||||

| ディスプレイ | 7インチ(IPS HD)タッチスクリーン | |||||

| メタルボタン | 銀メッキ接点、100,000サイクル以上 | |||||

| 安全保護 | アクリルドア+緊急停止 | |||||

| グラフ | 操作グラフ表示、USB Excelエクスポート | |||||

| プログラム制御 | 最大18ステップ | |||||

| 水冷 | 手動+自動急速冷却 | |||||

| 速度調整 | 調整可能な圧力/温度ランプレート | |||||

| リモートコントロール | オプションのコンピューターが必要 | |||||

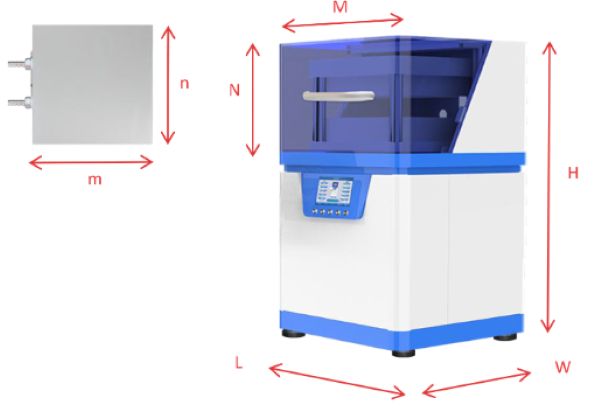

| プレートサイズ | 120 x 120 (m×n) | 180 x 180 mm(m×n) | 200 x 200 mm(m×n) | 300 x 300 mm(m×n) | 400 x 400 mm(m×n) | 500 x 500 mm(m×n) |

| 作業スペース | 130 x 55 mm | 210 x 65 mm | 210 x 65 mm | 320 x 70 mm | 420 x 90 mm | 520 x 100 mm |

| 電源 | 220V/110V(カスタマイズ可能) | |||||

| 製品寸法/重量 | 350x350x580 mm / 75 kg | 480x480x750 mm / 200 kg | 480x480x750 mm / 200 kg | 580x580x1180 mm / 580 kg | 680x680x1280 mm / 1130 kg | 780x780x1350 mm / 1808 kg |

| 梱包寸法/重量 | 725x620x890 mm / 84 kg | 725x620x890 mm / 236 kg | 725x620x890 mm / 236 kg | 900x800x1400 mm / 650 kg | 900x800x1400 mm / 1200 kg | 900x800x1400 mm / 1920 kg |

業界リーダーからの信頼

FAQ

油圧加熱式ラボラトリープレスを使用する利点は何ですか?

実験用電気プレスはどのように動作するのですか?

油圧ラボヒートプレスは何をするのですか?

電気ラボプレスを使用する利点は何ですか?

油圧加熱ラボプレスで処理できる試料や材料の種類は?

ラボ用電気プレスの用途は何ですか?

油圧加熱式ラボプレスの仕組み

ラボ用電動印刷機を選択する際には、どのような点に注意する必要がありますか?

油圧加熱ラボラトリープレスの性能はどのように最適化できますか?

4.9 / 5

This machine is a game-changer! The precision and speed are unmatched. Worth every penny!

4.8 / 5

Incredible quality and durability. It’s like having a lab assistant that never tires!

4.7 / 5

Fast delivery and easy setup. The advanced features make our research so much more efficient.

4.9 / 5

The technological advancements in this press are mind-blowing. A must-have for any serious lab.

4.8 / 5

Superb value for money. The programmable workflows save us hours of manual work.

4.7 / 5

The safety features are top-notch. We feel completely secure using it daily.

4.9 / 5

The thermal management is exceptional. Perfect for our high-temperature applications.

4.8 / 5

Robust construction and reliable performance. It’s a cornerstone of our lab now.

4.7 / 5

The interface is so intuitive. Even our newest team members can operate it with ease.

4.9 / 5

The scalability is fantastic. It grows with our needs, making it a long-term investment.

引用を要求

弊社の専門チームが 1 営業日以内にご返信いたします。 お気軽にお問い合わせ下さい!

関連製品

真空ボックス実験室用ホットプレス用加熱プレート付き加熱油圧プレス機

真空ボックス用ラボプレスで実験室の精度を高めましょう。真空環境で錠剤や粉末を簡単かつ正確にプレスし、酸化を軽減し、一貫性を向上させます。デジタル圧力計を備え、コンパクトで使いやすいです。

30T 40T 分割自動加熱油圧プレス機(加熱プレート付き)実験室用ホットプレス

材料研究、製薬、セラミックス、エレクトロニクス産業における精密なサンプル準備のための、分割自動加熱ラボプレス30T/40Tをご覧ください。設置面積が小さく、最大300℃まで加熱できるため、真空環境下での処理に最適です。

ラボ用加熱プレート付き自動高温加熱油圧プレス機

高温ホットプレスは、高温環境下での材料のプレス、焼結、加工に特化して設計された機械です。さまざまな高温プロセス要件に対応するため、摂氏数百度から摂氏数千度の範囲で動作可能です。

自動ラボ用コールドアイソスタティックプレス CIP装置 コールドアイソスタティックプレス

自動ラボ用コールドアイソスタティックプレスで効率的にサンプルを準備しましょう。材料研究、製薬、電子産業で広く使用されています。電気式CIPと比較して、より高い柔軟性と制御性を提供します。

電気実験室用コールドアイソスタティックプレス CIP装置

当社の電気実験室用コールドアイソスタティックプレスで、機械的特性が向上した高密度で均一な部品を製造しましょう。材料研究、製薬、電子産業で広く使用されています。効率的でコンパクト、真空対応です。

小型ラボ用ゴムカレンダー加工機

小型ラボ用ゴムカレンダー加工機は、プラスチックまたはゴム材料の薄く連続したシートを製造するために使用されます。薄膜、コーティング、ラミネートを精密な厚さと表面仕上げで作成するために、一般的に実験室、小規模生産施設、プロトタイピング環境で使用されます。

ラボ用小型射出成形機

小型射出成形機は、高速で安定した動作、優れた制御性と再現性、超省エネルギーを備えています。製品は自動的に落下・成形され、本体が低いため、給餌が容易で、メンテナンスも簡単で、設置場所の高さ制限もありません。

実験室用プラネタリーボールミルキャビネット プラネタリーボールミル

人間工学に基づいたデザインと垂直キャビネット構造により、立位での操作で最高の快適体験を提供します。最大処理容量は2000ml、回転数は毎分1200回転です。

実験室用水平遊星ボールミル粉砕機

水平遊星ボールミルでサンプルの均一性を向上させます。KT-P400Hはサンプルの堆積を軽減し、KT-P400Eは多方向機能を備えています。過負荷保護により、安全、便利、効率的です。

実験室用プラネタリーボールミル 回転ボールミル

KT-P400Eは、独自の粉砕・混合能力を持つデスクトップ型多方向プラネタリーボールミルです。連続・断続運転、タイマー、過負荷保護機能を備え、様々な用途に最適です。

乾式・湿式三次元ふるい分け用実験用振動ふるい機

KT-VD200は、実験室での乾式および湿式サンプルのふるい分け作業に使用できます。ふるい分け能力は20g〜3kgです。本製品は、独自の機械構造と毎分3000回の振動周波数を持つ電磁振動体を備えています。

ラボスケールロータリー単発打錠機 TDP打錠機

この機械は、粒状の原料を様々な錠剤に圧縮する単圧自動回転連続打錠機です。主に製薬業界での錠剤製造に使用され、化学、食品、電子機器などの産業分野にも適しています。

小型ワーク生産用コールド等方圧プレス機 CIP 400MPa

コールド等方圧プレス機で、均一に高密度の材料を生産します。生産現場での小型ワークピースの圧縮に最適です。高圧滅菌やタンパク質活性化のために、粉末冶金、セラミックス、バイオ医薬品分野で広く使用されています。

コールドアイソスタティックプレス用電気分割ラボコールドアイソスタティックプレスCIP装置

分割型コールドアイソスタティックプレスは、より高い圧力を供給できるため、高圧レベルを必要とする試験用途に適しています。

関連記事

欠陥のない材料の物理学:油圧ホットプレスの解体

油圧ホットプレスにおけるパスカルの原理と熱エネルギーの相乗効果が、精密で再現性の高い材料接合と成形をどのように可能にするかを発見してください。

実験室規模の接着が失敗する理由:熱と圧力の隠された物理学

ラミネートや複合材の剥離やボイドに悩んでいませんか?根本原因を発見し、完璧で再現可能な結果を最終的に達成する方法をご覧ください。

暴力ではなく、完璧な材料接合の制御された物理学

ホットプレスは単なるヒーターとプレスではありません。それは、完璧で再現可能な材料接合のために、制御された熱と力を統合するシステムです。

成形部品が失敗する理由:熱と圧力に隠された真実

反りや一貫性のない部品に悩んでいませんか?圧力が問題ではない理由と、油圧プレスにおける精密な熱制御が鍵となる理由を学びましょう。

ホットプレスサンプルの失敗:材料研究開発における隠れた原因

複合材またはラミネートサンプルの失敗にうんざりしていませんか?一貫性のない結果の隠れた原因と、適切なラボ用ホットプレスが再現性のある成功をどのように保証するかを発見してください。

圧力と熱:物質に確実性を鍛える

熱間プレスは単に材料を成形するだけでなく、隠れた欠陥を除去し、原子レベルの信頼性を鍛えます。材料の完全性の物理学を学びましょう。

実験装置が突然故障する理由:品質の問題ではなく、物理学の問題です

実験装置の故障に悩んでいませんか?それらを引き起こす圧力と強度に関する隠れた物理学を発見し、精密工学ソリューションが遅延を防ぐ方法を学びましょう。

複合材・ポリマー部品が破損し続ける理由:その秘訣は熱と圧力の同時印加にあり

複合材やポリマーの接着不良に悩んでいませんか?個別の加熱とプレスが失敗する理由と、ホット油圧プレスがどのように再現性の高い高品質な結果を保証するかをご覧ください。

ラボプレスが故障する理由:トン数ではなく、鋼材の問題

油圧プレスで一貫性のない結果が得られる隠れた理由を発見してください。安全性と精度にとって、鋼材の選択がトン数よりも重要である理由を学びましょう。

圧力と温度の対話:材料の固化をマスターする

熱間プレスが固定値ではなく、温度、圧力、そして材料固有の特性との精密な対話であることを学びましょう。

隠された欠陥:高性能金属部品が故障する理由と真の材料完全性を達成する方法

3Dプリントまたは鋳造された金属部品は完璧に見えるのに、予期せず故障しますか?不整合の隠された原因を発見し、熱間等方圧間接(HIP)が完全な信頼性をどのように保証するかをご覧ください。

最大圧力のその先へ:ホット等方圧プレス(HIP)の結果が一貫しない理由と改善策

HIPの結果の一貫性に悩んでいませんか?最大圧力が解決策ではない理由と、圧力、温度、時間の制御がいかに材料の完全な緻密化の鍵となるかを発見してください。