電気的故障

温度異常

真空炉の温度異常は、高温アラームまたはシステムが設定温度に到達できないこととして現れます。このような問題は炉の運転と効率を著しく低下させ、生産遅延やメンテナンスコストの増加につながる可能性があります。

高温アラームに対処するには、サーモスタットの精度と機能を確認することが重要です。これには、サーモスタットのパラメーターが正しく設定され、温度変化に適切に対応していることを確認するための校正が含まれます。さらに、ソリッド・ステート・リレー出力の点検も不可欠である。ソリッドステート・リレーが誤動作すると、温度制御が不安定になり、誤報につながる可能性がある。これらのコンポーネントの定期的なメンテナンスとテストにより、このような問題を防ぐことができる。

一方、炉が所望の温度に到達できない場合は、熱電対プローブを徹底的にチェックする必要があります。熱電対は炉内の実温度を測定する上で非常に重要です。熱電対が損傷していたり、校正が不適切であったりすると、読み取り値が不正確になり、効果的な温度制御ができなくなります。熱電対プローブを交換または再校正することで、この問題を解決し、正確な温度制御を確保することができます。

要約すると、真空炉の正確な温度制御を維持するには、温度異常の診断と解決への体系的なアプローチが必要です。サーモスタットパラメーター、ソリッドステートリレー出力、熱電対プローブに注目することで、オペレーターは炉の効率的かつ効果的な運転を確保することができます。

真空異常

炉の真空異常は炉の性能と効率に大きな影響を与えます。このような問題は通常、真空ポンプの動作不良や真空レベルの低下として現れ、最適な処理条件とはならない可能性があります。このような問題に対処するには、根本的な原因を特定し修正するための体系的なアプローチが必要です。

真空異常のトラブルシューティングの最初のステップの一つは、空気源の検査です。空気供給源が清潔で、汚染物質がないことを確認することで、真空システムの閉塞を防ぐことができる。さらに、真空ゲージの精度と較正をチェックする必要があります。不適切に較正されたゲージは、オペレーターを惑わし、誤った調整や継続的な問題を引き起こす可能性がある。

ドアシールの完全性も重要な要素である。ドアシールに欠陥があると、チャンバー内に空気が漏れ、真空レベルが低下します。シーリングテープの状態やドアプレートのアライメントをチェックするなど、ドアシールの定期的な検査とメンテナンスは不可欠な予防策である。

最後に、配管システムに摩耗や損傷の兆候がないか検査する必要がある。配管の損傷や接続不良は、空気漏れの原因となり、全体的な真空効率を低下させる。すべての接続が確実で、目に見えるひび割れや穴がないことを確認することで、最適な真空レベルを維持することができます。

空気源、真空計、ドアシール、配管など、これらの領域に体系的に対処することで、オペレーターは真空の異常を効果的に解消し、真空炉のスムーズな運転を確保することができます。

機械構造の不具合

ドアの問題

真空炉を扱う際、最も一般的な機械的構造不良のひとつはドアが適切に密閉されないことです。この問題は操業の大幅な非効率と潜在的な安全ハザードにつながる可能性があります。この問題の主な解決策には、いくつかの主要部品の徹底的な点検が含まれます。

第一に ドアヒンジ は、摩耗やずれの兆候がないか検査する必要がある。適切なアライメントは、ドアが均一かつ確実に閉まるために極めて重要である。ヒンジが摩耗していたり緩んでいたりする場合は、適切な機能を回復させるために、締め付けるか交換する必要があるかもしれません。

次へ プル・バックル は、ドアが効果的に密閉されるために重要な役割を果たします。これらのバックルはドアを所定の位置に固定するのに役立ち、不具合があると密閉性が悪くなります。プル・バックルが正しく機能しているか、障害や損傷がないかをチェックすることが重要です。

シーリング・テープ も点検が必要な重要部品である。シーリングテープは時間の経過とともに劣化したり、位置がずれて漏れにつながることがあります。シーリング・テープの状態とアライメントを定期的にチェックすることで、この問題を未然に防ぐことができる。テープが摩耗したり損傷している場合は、密閉性を確保するために速やかに交換する必要がある。

最後に ドアプレート 自体に変形や損傷がないか点検する必要がある。ドアプレートに凹凸があると、適切に密閉する能力に影響を及ぼす可能性がある。ドア・プレートが良好な状態にあり、適切に調整されていることを確認することは、効果的なシールを維持するために不可欠である。

これらの構成部品を体系的に点検することで、オペレーターはドアが適切に密閉されない問題に対処し解決することができ、真空炉の効率と安全性を維持することができます。

ファンの不具合

ファンから発せられる異音は、真空炉内の潜在的な故障の初期指標となり得ます。このような異音は、しばしばガリガリ、ガラガラ、ヒュンヒュンと表現されますが、様々な問題に起因している可能性があり、放置すると、より深刻な動作上の問題につながる可能性があります。

このような音の主な原因の一つは、ファンアセンブリ内の異物の存在です。時間の経過とともに、ホコリや金属くずなどのゴミが蓄積し、ファンブレードやハウジングに詰まることがあります。このような異物の侵入により、ファンの動作が不均一になり、特徴的な異音が発生することがあります。このような問題を防ぐには、異物の除去を含む定期的な点検とメンテナンスが重要です。

ファンに関連する異音のもう一つの一般的な原因は、モーターのネジの緩みである。炉内の絶え間ない振動や動きによって、これらのネジは時間の経過とともに外れたり緩んだりします。この緩みは、ファンが回転する際にガラガラという音を発生させ、早急な対処が必要であることを知らせます。これらのネジを締めることで、多くの場合問題は解決しますが、将来的な発生を防ぐために、すべての部品がしっかりと固定されていることを確認することが不可欠です。

| 問題点 | 考えられる原因 | 解決方法 |

|---|---|---|

| 異音 | ファン内の異物 | ゴミを取り除き、アセンブリを清掃する |

| モーターのネジが緩んでいる | すべてのネジを締めて部品を固定する |

真空炉の効率と寿命を維持するためには、こうしたファンの不具合に迅速に対処することが重要です。徹底的な点検と必要な調整を含む定期的なメンテナンススケジュールは、些細な問題が重大な問題に発展するのを防ぐのに役立ちます。

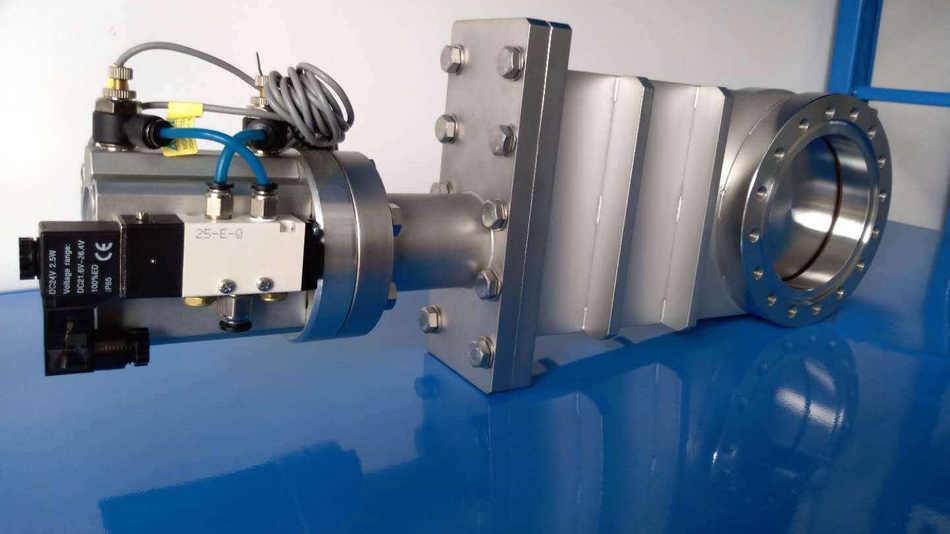

空気圧バルブの故障

真空炉の空気圧バルブの不具合は操業を中断させ、大幅なダウンタイムにつながります。このような不具合は多くの場合、バルブが要求通りに開閉せず、システムが望ましい真空レベルとプロセス条件を維持する能力に影響を与えます。

これらの問題を診断し解決するために、技術者はまずソレノイドバルブを点検する必要があります。これらのバルブは、圧縮空気の流れを制御する重要なコンポーネントであり、誤動作は空気圧システム全体を動作不能にする可能性があります。一般的な問題には、ソレノイドの固着や損傷があり、洗浄、修理、交換が必要になる場合があります。

さらに、圧縮空気供給の適切な圧力を確保することも重要です。圧力不足または圧力過剰は、バルブが不適切に機能する原因となります。空気圧の定期的なチェックと調整、および空気圧縮機と関連配管のメンテナンスは、空気圧バルブの一般的な故障の多くを防ぐことができます。

要約すると、空気圧バルブの故障に対処するには、電磁弁の徹底的な検査と圧縮空気圧が指定範囲内であることを確認することから始める体系的なアプローチが必要です。