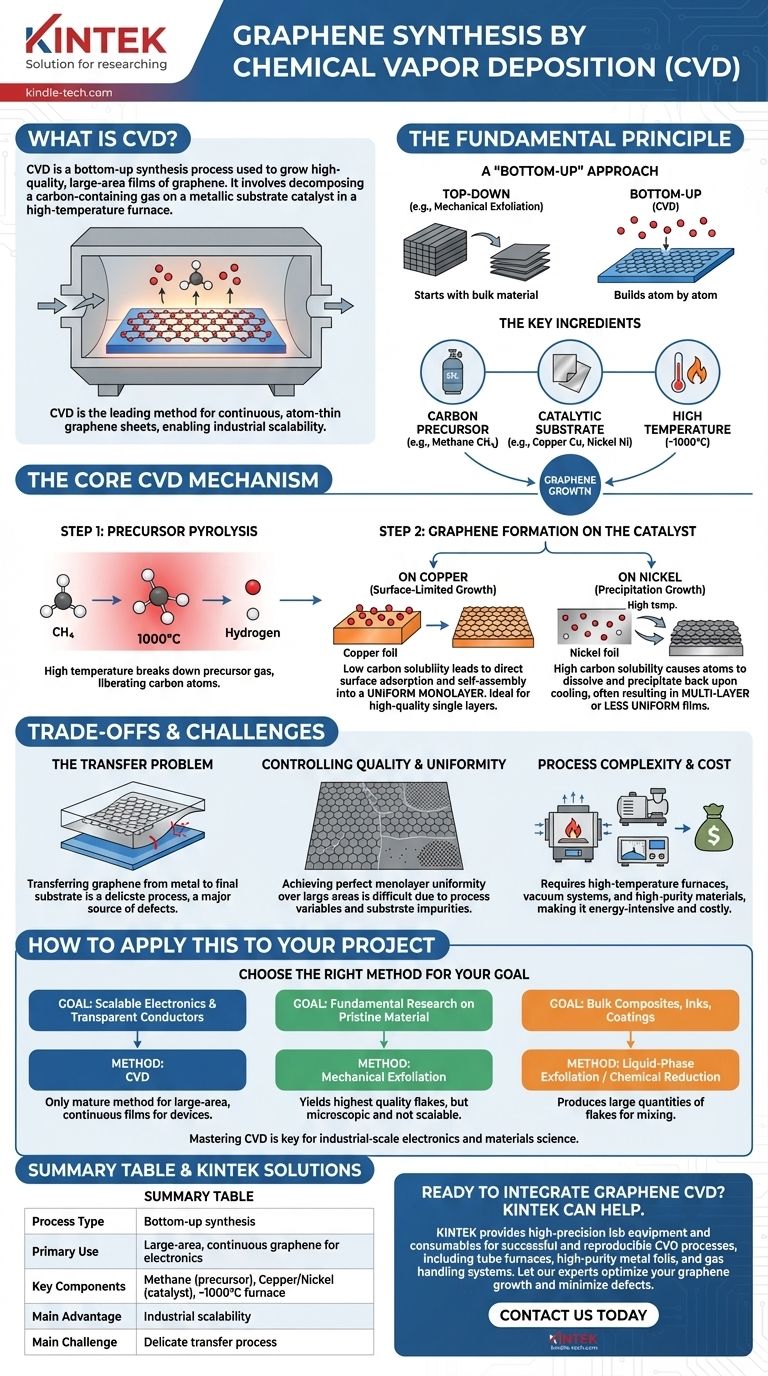

要するに、化学気相成長法(CVD)は、高品質で大面積のグラフェンフィルムを成長させるために使用される合成プロセスです。炭素含有ガス(前駆体)を高温炉に導入し、そこで触媒として機能する金属基板の表面で分解させます。これらの分解された炭素原子は、グラフェンの六角格子構造に配列されます。

化学気相成長法は、グラフェンを粉末としてではなく、連続した原子層のシートとして製造するための主要な工業的手法です。その主な利点はスケーラビリティであり、他のほとんどの方法では達成できない、電子用途に十分な大きさのフィルムを作成できます。

基本原理:原子から原子へグラフェンを構築する

「ボトムアップ」アプローチ

グラフェン合成は、「トップダウン」と「ボトムアップ」の2つのカテゴリに大別されます。

機械的剥離のようなトップダウン法は、大きなグラファイトの塊から始めて、それを単層に分解します。対照的に、CVDはボトムアップ法です。ガス中の個々の炭素原子から始めて、モザイクを形成するために個々のタイルを敷き詰めるように、グラフェン構造を一から構築します。

主要な要素

グラフェンCVDプロセスは、連携して機能する3つの主要なコンポーネントに依存しています。

- 炭素前駆体:炭素原子の供給源となる炭化水素ガスで、最も一般的にはメタン(CH₄)です。

- 触媒基板:グラフェンが成長する遷移金属箔で、通常は銅(Cu)またはニッケル(Ni)です。金属の役割は、反応に必要なエネルギーを劇的に低減することです。

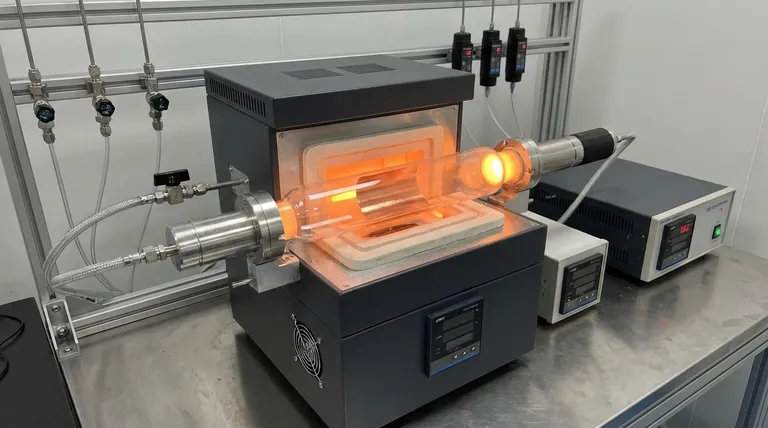

- 高温:プロセスは、前駆体ガスを分解し、原子の配列を促進するために必要なエネルギーを供給するため、しばしば1000°Cに近づく温度の炉で行われます。

CVDの核となるメカニズム

CVDによるグラフェンの合成は、反応チャンバー内で発生する2段階のプロセスです。

ステップ1:前駆体の熱分解

まず、高温により前駆体ガスが分解されます。例えば、メタンは炭素原子と水素原子に分解されます。

このステップは熱分解として知られており、グラフェンシートの構築に使用される個々の炭素原子を効果的に放出します。

ステップ2:触媒上でのグラフェン形成

解放された炭素原子は、金属基板上にグラフェン格子を形成します。正確なメカニズムは、選択された金属に大きく依存します。

銅上では、成長は表面限定プロセスです。炭素は銅への溶解度が非常に低いため、原子は箔の表面に直接吸着し、均一な単層のグラフェンに自己組織化します。これにより、銅は高品質の単層フィルムの製造に理想的です。

ニッケル上では、メカニズムが異なります。炭素はニッケルへの溶解度が高いため、原子はまず高温でバルク金属に溶解します。金属が冷却されると、炭素の溶解度が低下し、溶解した原子が表面に析出するように強制され、そこでグラフェン層を形成します。これにより、多層または均一性の低いフィルムが生成される可能性があります。

トレードオフと課題を理解する

CVDは強力ですが、その複雑さと限界がないわけではありません。これらのトレードオフを理解することは、あらゆる実用的なアプリケーションにとって不可欠です。

転写の問題

CVDで成長したグラフェンは金属箔上に形成されますが、ほとんどの電子アプリケーションでは、二酸化ケイ素のような絶縁性基板上に配置する必要があります。これには転写プロセスが必要です。

グラフェンフィルムは、金属から慎重に持ち上げられ、最終的な基板に移動させる必要があります。このデリケートなステップは、グラフェンの優れた特性を劣化させる可能性のある欠陥、しわ、破れ、汚染の主な原因となります。

品質と均一性の制御

大面積にわたって完全に均一で欠陥のない単層を達成することは非常に困難です。

ガス流量、温度勾配、金属箔の純度などの要因により、多層パッチ、粒界(異なる成長ドメイン間の継ぎ目)、および原子格子内の空孔が形成される可能性があります。フィルムの電気的特性は、この構造的品質に大きく依存します。

プロセスの複雑さとコスト

CVDには、高温炉、真空システム、精密なガス流量制御装置などの特殊な装置が必要です。高純度金属箔の必要性とプロセスのエネルギー集約的な性質が、その全体的なコストと複雑さに寄与しています。

これをプロジェクトに適用する方法

最適な合成方法は、最終目標に完全に依存します。CVDは強力なツールですが、万能な解決策ではありません。

- スケーラブルなエレクトロニクスまたは透明導体に重点を置く場合:CVDが最も実行可能な方法です。タッチスクリーン、センサー、次世代トランジスタなどのデバイスに必要な大面積の連続グラフェンフィルムを製造するための唯一の成熟した方法です。

- 純粋な材料に関する基礎研究に重点を置く場合:機械的剥離(「スコッチテープ法」)が優れています。これは最高品質で最も電子的に完璧なグラフェンフレークを生成しますが、それらは微視的であり、スケーラブルではありません。

- バルク複合材料、インク、またはコーティングに重点を置く場合:液相剥離または酸化グラフェンの化学還元がより良い選択肢です。これらのトップダウン法は、ポリマー、塗料、またはバッテリーに混合するのに理想的な大量のグラフェンフレークを生成します。

最終的に、CVDを習得することは、産業規模でエレクトロニクスと材料科学を変革するためのグラフェンの可能性を解き放つ鍵となります。

要約表:

| 側面 | 主要な詳細 |

|---|---|

| プロセスタイプ | ボトムアップ合成 |

| 主な用途 | エレクトロニクス用大面積連続グラフェンフィルム |

| 主要コンポーネント | メタン(前駆体)、銅/ニッケル(触媒)、〜1000°Cの炉 |

| 主な利点 | 産業規模でのスケーラビリティ |

| 主な課題 | 最終基板へのデリケートな転写プロセス |

グラフェンCVDをラボワークフローに統合する準備はできましたか?

高品質グラフェンの合成を習得することは、次世代エレクトロニクスと材料科学にとって極めて重要です。KINTEKは、チューブ炉から高純度金属箔、ガス供給システムまで、成功し再現性のあるCVDプロセスに不可欠な高精度ラボ機器と消耗品の提供を専門としています。

お客様の研究開発目標達成を支援させてください。当社の専門家が、グラフェン成長を最適化し、均一性を確保し、欠陥を最小限に抑えるための適切なツールの選択をお手伝いします。

お問い合わせフォームから今すぐご連絡ください。お客様の特定のラボニーズと、KINTEKが高度な材料におけるイノベーションをどのようにサポートできるかについてご相談ください。

ビジュアルガイド

関連製品

- 化学気相成長 CVD装置 システムチャンバースライド PECVDチューブファーネス 液体ガス化装置付き PECVDマシン

- RF PECVDシステム RFプラズマエッチング装置

- 顧客メイド多用途CVDチューブ炉 化学気相成長チャンバーシステム装置

- 真空ステーション付き分割チャンバーCVDチューブ炉 化学蒸着システム装置

- 石英管付き1200℃分割管状炉 ラボ用管状炉