本質的に、金属焼結炉とは、金属粉末を完全に溶かすことなく、それを固体で高密度の物体に変える、高度に制御された産業用オーブンです。個々の粉末粒子が原子レベルで結合するように、正確に管理された熱、雰囲気、場合によっては圧力を利用します。これは焼結として知られるプロセスです。この技術は粉末冶金の礎であり、複雑なニアネットシェイプの金属部品の作成を可能にします。

焼結炉は単なる「熱い箱」ではありません。それは材料の微細構造を操作するために設計された洗練されたシステムです。その主な機能は、粉末状の金属が強力で機能的なコンポーネントに融合するための制御された環境を作り出すことであり、しばしば従来の鋳造や機械加工では達成が難しい特性を持ちます。

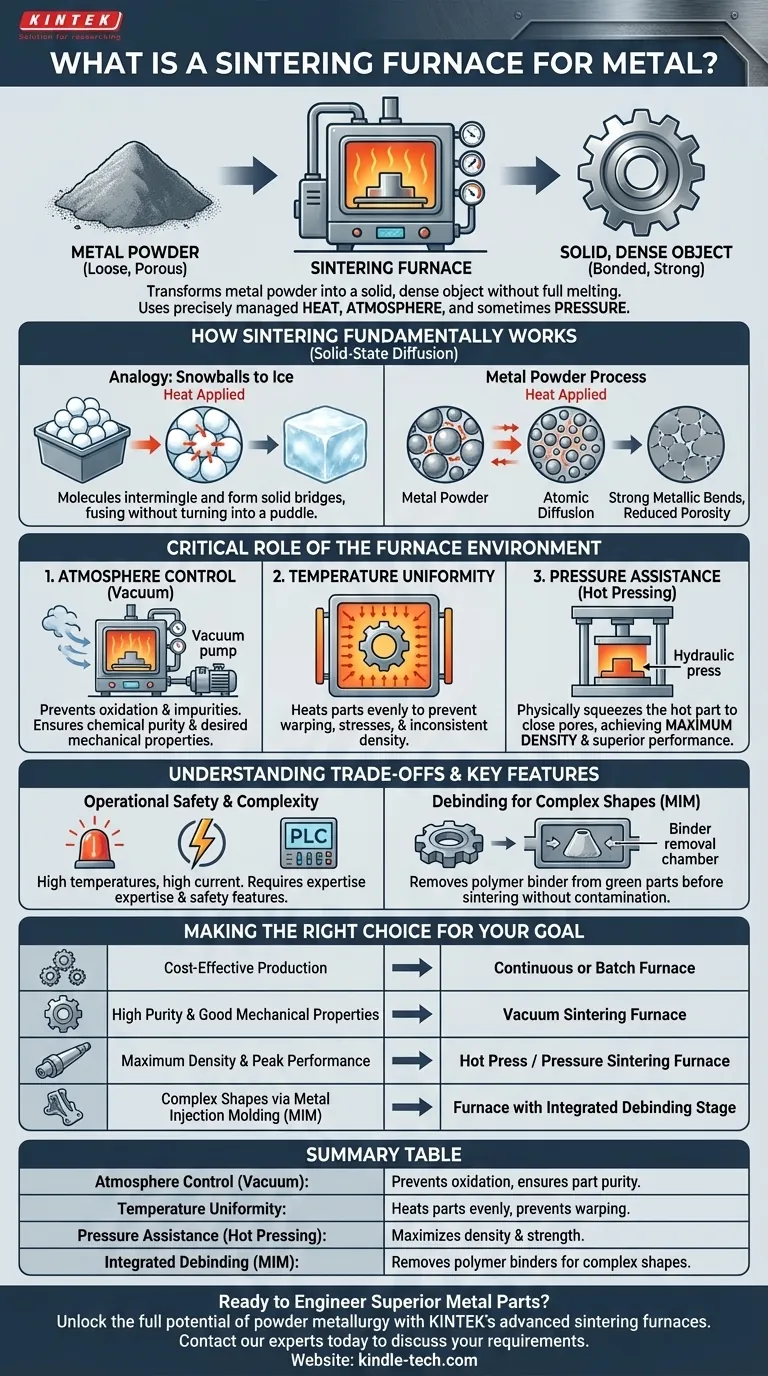

焼結の基本的な仕組み

このプロセスは、単に材料を加熱するよりも複雑です。それは固相拡散と呼ばれる原理に依存しており、これは金属の融点以下の温度で起こります。

原子拡散の原理

寒い日に、ぎっしり詰まった雪玉の山を想像してください。温度がわずかに上昇すると、各雪玉の外側の分子がより活発になります。雪玉がお互いに接触する場所で、これらの分子は混ざり合い、固体の氷の橋を形成し、水たまりになることなく、個々の玉を単一の固体の塊に融合させます。

焼結も同様の方法で機能します。炉は圧縮された金属粉末を加熱し、原子が個々の粒子の境界を横切って移動するのに十分なエネルギーを与え、強力な金属結合を形成し、緩い粉末を固体部品に変えます。

目標:密度と強度

粒子が結合するにつれて、それらの間の隙間(または空隙)が縮小します。焼結の究極の目標は、この多孔性を排除し、可能な限り高密度で強力な部品を達成することです。炉のすべての特徴は、このプロセスを最適化するように設計されています。

炉内環境の重要な役割

焼結部品の品質は、炉内の条件に完全に依存します。最新の炉は、雰囲気、温度、圧力という3つの主要な変数を正確に制御できます。

雰囲気の制御:真空の力

高性能焼結のほとんどは真空下で行われます。空気を除去することで、炉は酸素が熱い金属と反応するのを防ぎます。酸素との反応は、酸化(錆のようなもの)やその他の不純物を引き起こします。

真空環境は最終部品の化学的純度を保証し、これは強度や疲労耐性などの望ましい機械的特性を達成するために不可欠です。

温度均一性の影響

炉は部品を全方向から均一に加熱する必要があります。ある領域が別の領域よりも熱い場合、その領域はより速く焼結し、内部応力、反り、または不均一な密度につながります。

高度な炉は、特殊な発熱体と断熱材を使用して、ホットゾーン全体で優れた温度均一性を保証し、部品が予測可能に焼結されるようにします。

圧力の役割:最大密度の達成

熱だけで部品が作成できる場合もありますが、加熱サイクル中に外部圧力をかけると、最終的な密度が劇的に向上します。これは圧力支援焼結または熱間プレスとして知られています。

部品が熱くて成形可能な間に物理的に圧縮することにより、このプロセスは残りの空隙をより効果的に閉じ、優れた機械的性能をもたらします。これは、航空宇宙や医療用インプラントなどの要求の厳しい用途のコンポーネントに不可欠です。

トレードオフと主要機能の理解

焼結炉は複雑で強力な装置であり、その操作には重要な考慮事項が伴います。

運転の安全性は最優先事項

これらの炉は非常に高い温度で長期間動作し、非常に高い電流を消費します。安全性は主要な設計特徴であり、過熱アラーム、自動圧力保護、および事故を防ぐためのインターロックが組み込まれています。

複雑性とプロセス制御

最新の炉は、材料科学、真空技術、高圧システム、および洗練されたPLC制御を組み合わせた学際的なシステムです。これらは単純な「プラグアンドプレイ」マシンではありません。

再現性のある高品質の結果を達成するには、プロセス開発の専門知識と、炉のパラメータが最終的な材料特性にどのように影響するかについての深い理解が必要です。

複雑な形状のための脱脂

金属射出成形(MIM)などの製造方法では、初期の「グリーン」部品には金属粉末と混合されたポリマーバインダーが含まれています。このバインダーは焼結前に除去する必要があります。

多くの炉には、部品を穏やかに加熱し、炉の主要な加熱室を汚染することなくこのバインダーを除去するための特別な密閉された「脱脂マッフル」が組み込まれています。

目標に応じた適切な選択

適切な焼結プロセスを選択することは、最終コンポーネントの要件に完全に依存します。

- コスト効率の高い標準部品の製造が主な焦点である場合: 大気制御が基本的な連続炉またはバッチ炉で十分な場合があります。

- 高純度と良好な機械的特性が主な焦点である場合: 真空焼結炉は、クリーンで強力な部品を製造するための業界標準です。

- 要求の厳しい用途で最大密度と最高の性能が主な焦点である場合: 理論値に近い密度を達成するには、熱プレスまたは圧力焼結炉が必要です。

- 金属射出成形(MIM)による複雑な形状の作成が主な焦点である場合: 統合された脱脂ステージを備えた炉は、プロセスを成功させるために不可欠です。

最終的に、焼結プロセスを習得することは、比類のない精度と性能で次世代の金属コンポーネントを設計および製造する能力を解き放ちます。

要約表:

| 特徴 | 目的と利点 |

|---|---|

| 雰囲気制御(真空) | 酸化を防ぎ、部品の純度と優れた機械的特性を保証します。 |

| 温度均一性 | 部品を均一に加熱し、反りを防ぎ、一貫した密度を保証します。 |

| 圧力支援(熱間プレス) | 要求の厳しい用途で最大密度と強度を実現します。 |

| 統合脱脂(MIM用) | 汚染なしに複雑な形状のポリマーバインダーを除去します。 |

優れた金属部品の設計にご興味がありますか?

あなたの研究室または生産ラインのために粉末冶金の可能性を最大限に引き出しましょう。KINTEKは、部品の最大密度、純度、性能を達成するために必要な正確な制御を提供する、高度な焼結炉および実験装置を専門としています。

お客様固有の金属焼結要件についてご相談いただき、用途に最適なソリューションを見つけるために、今すぐ専門家にお問い合わせください。

ビジュアルガイド

関連製品

- 9MPa空気圧焼結炉(真空熱処理付)

- スパークプラズマ焼結炉 SPS炉

- 熱処理・焼結用600T真空誘導熱プレス炉

- 真空熱処理・モリブデン線焼結炉(真空焼結用)

- トランス付きチェアサイド用歯科用ポーセリンジルコニア焼結セラミックファーネス