最も一般的な方法は、ポリマー支持層(通常はPMMA)を使用して、単原子層の膜を成長基板からターゲット基板へ移動させることです。グラフェンをPMMAでコーティングした後、元の成長基板を化学的にエッチングして除去し、浮遊するPMMA/グラフェン膜を残します。この膜を新しい表面に注意深く配置してから、PMMAを溶解します。

グラフェン転写の核心的な課題は、壊れやすい原子一層のシートを、その優れた特性を劣化させるようなしわ、破れ、化学的汚染を導入することなく、ある表面から別の表面へ移動させることです。

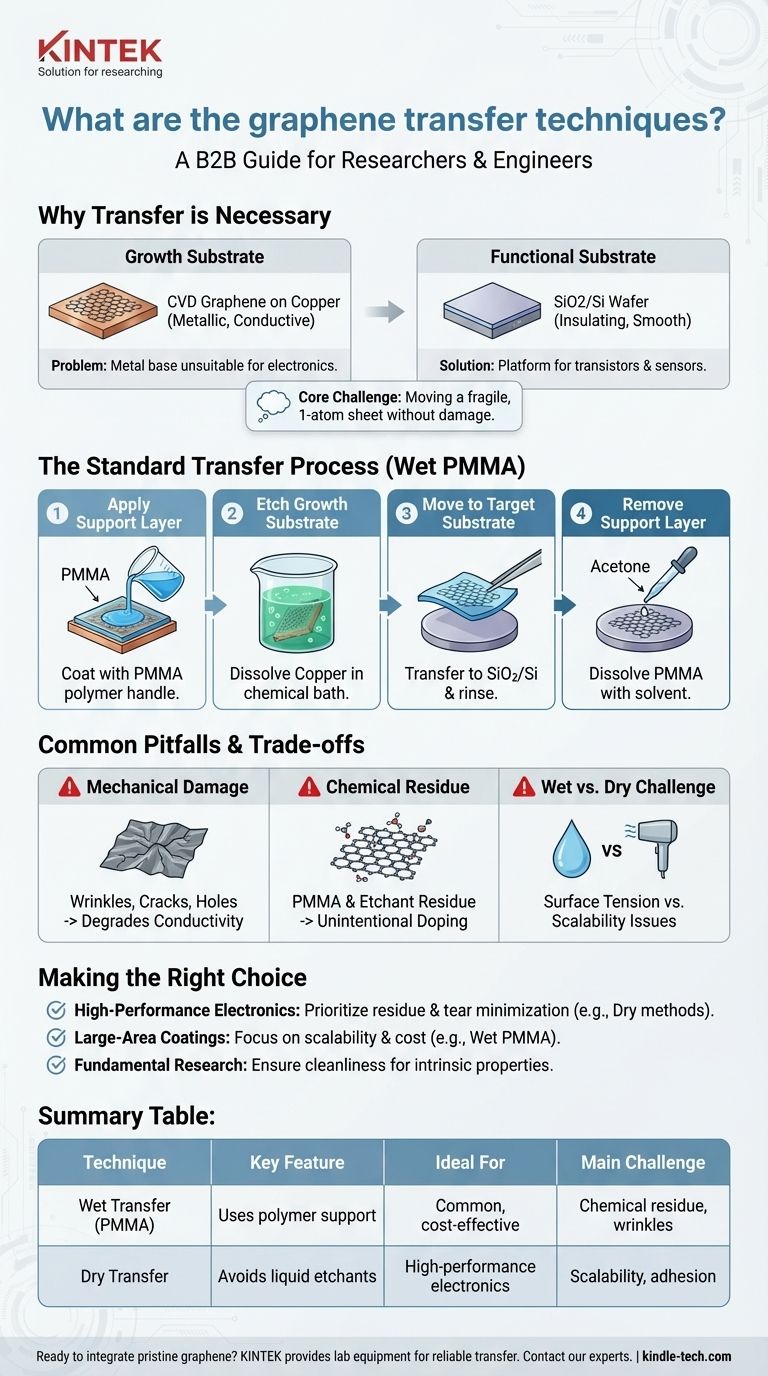

グラフェン転写が必要な理由

成長基板の問題

グラフェンは、多くの場合、化学気相成長法(CVD)などの方法で合成されます。この方法では、銅箔などの金属触媒上に薄膜として成長します。

成長には優れていますが、これらの金属基板は、特に絶縁体または半導体のベースが必要なエレクトロニクス分野において、グラフェンの最終用途には適していません。

機能性基板への移動

トランジスタ、センサー、その他のデバイスを構築するためには、グラフェンを機能性ターゲット基板へ移動させる必要があります。

酸化物層(SiO2/Si)付きシリコンウェハは、絶縁性があり、非常に滑らかな表面を持ち、半導体産業全体の標準的なプラットフォームであるため、一般的な選択肢です。転写プロセスは、グラフェン合成と実用的な応用との間の重要な架け橋となります。

標準的な転写プロセスの構造

最も確立されている技術は、「ウェット転写」であり、ポリマーの足場を使用してグラフェン膜を支持します。

ステップ1:支持層の適用

ポリマー溶液、最も一般的にはポリメタクリル酸メチル(PMMA)を、元の成長基板上にあるグラフェン膜の真上に直接コーティングします。

このPMMA層は一時的なハンドルおよび機械的支持として機能し、超薄いグラフェンが後続のステップ中に折りたたまれたり、破れたり、崩壊したりするのを防ぎます。

ステップ2:成長基板のエッチング

サンプル全体(PMMA/グラフェン/銅)を化学浴、すなわちエッチャントに浸し、元の成長基板を選択的に溶解させます。

銅基板の場合、塩化第二鉄や過硫酸アンモニウムなどのエッチャントが使用されます。このプロセスにより、PMMA/グラフェン膜が液体の表面に浮遊した状態になります。

ステップ3:ターゲット基板への移動

浮遊している膜をエッチャント溶液から慎重に「釣り上げ」ます。多くの場合、ターゲットとなるSiO2/Si基板をその下に沈め、ゆっくりと持ち上げて取り出します。

その後、残留エッチャントを除去するために脱イオン水ですすぎ、新しい基板の上に慎重に広げます。

ステップ4:支持層の除去

膜がターゲット基板上にしっかりと配置されたら、最後のステップはPMMA支持層を除去することです。

これは通常、アセトンなどの溶媒でPMMAを溶解し、その後最終的にすすぎを行うことによって行われます。成功すれば、新しい基板上にはクリーンな単層グラフェンのみが残ります。

一般的な落とし穴とトレードオフ

完璧な転写は理想ですが、現実には、最終的なグラフェン膜の品質に影響を与える可能性のある重大な課題が伴います。

機械的損傷の問題

原子層のシートを取り扱うのは非常に困難です。転写中に導入されるしわ、亀裂、穴は一般的な欠陥です。

これらの不完全さは、グラフェンの連続的なハニカム格子を乱し、電気伝導率と機械的強度を低下させます。

化学残留物の問題

プロセスで使用される化学物質、すなわちPMMAとエッチャントは、残留物や汚染を残す可能性があります。

微量のポリマーや金属イオンでさえ、意図せずグラフェンを「ドーピング」し、その電子的特性を変化させ、デバイス性能を妨げる可能性があります。

ウェットとドライの課題

説明した標準的な「ウェット」転写プロセスは、液体からの表面張力を導入し、これがしわの原因となったり、慎重な乾燥を必要としたりします。

これにより、代替の「ドライ」転写方法が開発されましたが、これらもまた、スケーラビリティや膜の密着性に関してトレードオフを抱えていることがよくあります。ウェットPMMA法は、その比較的単純さと低コストから、依然として最も一般的です。

目的に合わせた適切な選択

転写プロセスで許容される欠陥のレベルは、意図された用途に完全に依存します。

- 高性能エレクトロニクスに重点を置く場合: 優先事項は、キャリア移動度とデバイスの信頼性に直接影響を与える化学残留物と機械的損傷を最小限に抑える転写プロセスである必要があります。

- 大面積コーティングまたは複合材料に重点を置く場合: スケーラビリティ、コスト、および大面積にわたる膜の連続性を維持することが、完全に純粋で欠陥のない単層を達成することよりも重要になります。

- 基礎研究に重点を置く場合: 転写のクリーンさと基板の選択は、実験測定がグラフェン固有の特性を反映し、プロセスの人工物を反映しないようにするために最も重要です。

結局のところ、グラフェンの真の可能性を引き出すためには、その成長をマスターすることと同じくらい、グラフェンの転写をマスターすることが重要です。

要約表:

| 技術 | 主な特徴 | 理想的な用途 | 主な課題 |

|---|---|---|---|

| ウェット転写(PMMA) | ポリマー支持層を使用 | 一般的な方法、費用対効果が高い | 化学残留物、しわ |

| ドライ転写 | 液体エッチャントを回避 | 高性能エレクトロニクス | スケーラビリティ、密着性 |

デバイスに純粋なグラフェンを統合する準備はできていますか? 適切な転写技術は性能にとって極めて重要です。KINTEKは、研究開発ラボにサービスを提供し、信頼性の高いグラフェン転写に必要なラボ機器と消耗品を提供することを専門としています。当社の専門家に今すぐお問い合わせいただき、お客様固有のアプリケーションニーズをサポートし、高品質な結果を保証する方法についてご相談ください。

ビジュアルガイド

関連製品

- 顧客メイド多用途CVDチューブ炉 化学気相成長チャンバーシステム装置

- 効率的なサンプル混合と均質化のための実験用ディスク回転ミキサー

- 小型ワーク生産用コールド等方圧プレス機 CIP 400MPa

- PTFE容器用カスタムPTFEテフロン部品メーカー

- 黒鉛真空連続黒鉛化炉