高純度酸化アルミニウム

ハイテク産業における用途

高純度アルミナ(HPA)は、様々なハイテク産業において幅広い用途に使用されており、それぞれがそのユニークな特性を活かして性能と信頼性を高めています。蛍光材料の分野では 蛍光材料 HPAは、LEDやプラズマディスプレイなど、さまざまな照明技術に不可欠な高品質の蛍光体を製造するために不可欠です。これらの蛍光体には、正確な化学的純度と構造的完全性が求められますが、HPAはその両方を満たしています。

また 透明セラミック HPAは、光学的透明性と機械的強度および熱的安定性を併せ持つ材料の製造に使用されています。そのため、透明鎧、高圧窓、医療用画像処理装置などの用途に最適です。これらのセラミックスの光学的透明性と耐久性は、その製造に使用されるアルミナの高純度に直接起因しています。

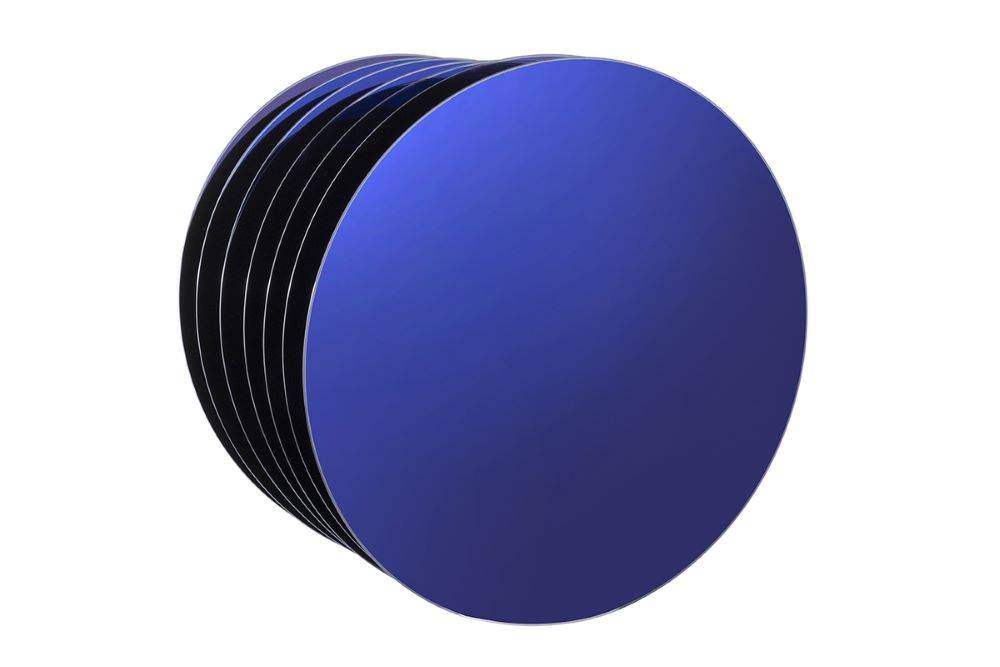

エレクトロニクス産業は、以下のような形でHPAから大きな恩恵を受けています。 電子機器 .高純度アルミナは、集積回路用基板の製造に使用され、優れた熱伝導性と誘電特性を提供します。これにより、電子部品は高ストレス条件下でも効率的かつ確実に動作します。さらに、HPAは、高度な電子デバイスの製造に不可欠な高品質の半導体結晶を成長させるためのるつぼの製造にも使用されています。

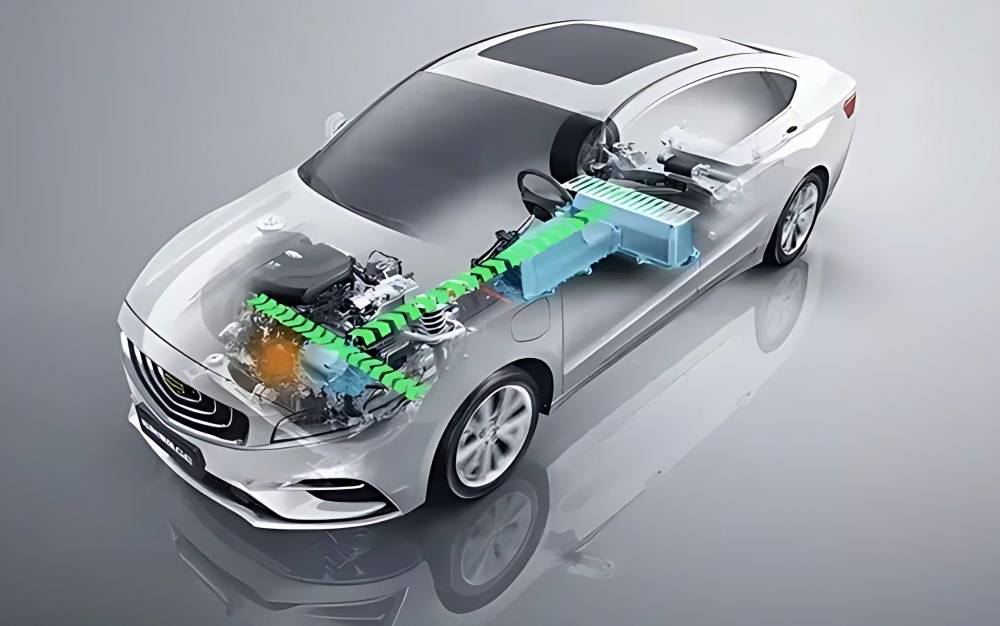

新エネルギー技術 もまた、さまざまな用途でHPAに依存しています。固体電池では、HPAが電解質の充填材として使用され、電池の性能と寿命を向上させます。HPAは高純度で安定性が高いため、動作中に過酷な条件にさらされる重要な部品に最適です。さらに、HPAは太陽電池の製造にも使用され、その光学特性が太陽エネルギーの変換効率に貢献しています。

触媒材料の分野では 触媒材料 HPAは触媒の担体材料として使用され、化学反応の効率を高める安定した多孔質構造を提供します。この用途は、石油化学や環境保護などの産業において特に重要であり、触媒プロセスはさまざまな化学物質を製造し、有害な排出を削減するために不可欠である。

最後に 航空宇宙材料 は、その卓越した機械的強度と耐熱性により、HPA の使用から利益を得ています。高純度アルミナは、高温や過酷な環境に耐えることが重要な熱保護システムなどの部品製造に使用されます。このため、HPAは航空宇宙車両の安全性と信頼性を確保するために不可欠な材料となっています。

全体として、これらのハイテク産業における高純度アルミナの多様な用途は、現代技術における多用途かつ不可欠な材料としてのその重要性を強調している。

市場動向と将来展望

サファイア市場、特にLED産業は、依然として高純度酸化アルミニウムの最大消費者である。この優位性は、発光と効率を高める高品質材料に対するLED業界の継続的な需要によるものである。世界のサファイア市場は大幅な成長が見込まれており、その規模は2024年までに107億ドルに達すると予想されている。この成長には、自動車照明、一般照明、家電製品など様々な用途でのLED採用の増加など、いくつかの要因がある。

さらに市場は、より優れた性能と耐久性を提供する、より高度なサファイア材料へのシフトを目の当たりにしている。この傾向は、高純度酸化アルミニウムをより入手しやすくし、費用対効果を高める製造技術の革新によって支えられている。さらに、エネルギー効率の高い照明ソリューションに対する需要の高まりが、市場をさらに前進させている。

地域別動向では、アジア太平洋地域が市場をリードすると予想される。これは、大手LEDメーカーの存在と、中国やインドのような国々における急速な工業化のためである。北米と欧州も重要な市場であり、厳しいエネルギー効率規制とスマート照明ソリューションの採用が拡大している。

全体として、サファイア市場の将来見通しは有望であり、高品質かつエネルギー効率の高い照明ソリューションへの需要が高まり続けていることから、持続的な成長が見込まれている。

新たな用途

高純度アルミナは伝統産業に革命を起こすだけでなく、最先端技術にも大きく進出している。電極添加材料として、導電性と安定性を向上させることで電池の性能を高めており、これは電気自動車や再生可能エネルギー貯蔵システムへの応用に不可欠である。さらに、固体電池の電解質フィラーとして使用することで、従来の液体電解質に代わる安全な電解質を提供し、熱暴走のリスクを低減して電池全体の安全性を高めることができる。

半導体産業において、高純度アルミナは研削・研磨工程に不可欠であり、高性能チップに要求される表面仕上げと寸法精度を保証します。この用途は、わずかな欠陥でさえデバイスの効率と信頼性を損なう可能性がある半導体技術の進歩におけるアルミナの役割を強調しています。

| 応用分野 | 利点 |

|---|---|

| 電極添加剤 | - 電池の導電性と安定性を高める |

| - 電気自動車や再生可能エネルギー貯蔵システムに不可欠 | |

| 固体電池電解質フィラー | - 液体電解質に代わる安全な電解質を提供 |

| - 電池の熱暴走リスクを低減 | |

| 半導体産業 | - 高性能チップの研削と研磨に不可欠 |

| - 表面仕上げと寸法精度を確保 |

これらの新たな用途は、エネルギー貯蔵と半導体技術の両方における高純度アルミナの多用途性と戦略的重要性を浮き彫りにしています。

ベーマイト

主な用途

主要な無機コーティング材料であるベーマイトは、リチウム電池隔膜業界で極めて重要な役割を果たしている。2022年の出荷量は32,000トンに急増し、前年比70%以上の著しい伸びを示した。この大幅な増加は、電池の性能と安全性を高める上でこの材料が極めて重要であることを裏付けている。

リチウム電池におけるベーマイトの主な役割は、ダイアフラムを補強し、高温下および急速な充放電サイクルにおいても安定性を維持することである。この安定性は、電気自動車やエネルギー貯蔵システムの用途に最も重要な短絡の防止と電池寿命の延長に極めて重要です。

さらに、高い熱安定性や様々な基材への優れた接着性など、ボーマイトのユニークな特性は、高度なバッテリー技術にとって理想的な選択肢となっている。高性能電池の需要が増加し続ける中、電池設計の革新や電気自動車の採用拡大により、ボエマイトの市場はさらに拡大すると予測されています。

まとめると、リチウム電池分野におけるボエマイトの力強い成長は、電池技術の進歩に不可欠な役割を果たし、より効率的で信頼性の高いエネルギー貯蔵ソリューションへの道を開くことを浮き彫りにしています。

今後の市場の可能性

新エネルギー自動車とエネルギー貯蔵システムの市場が急成長していることから、リチウムイオン電池のダイヤフラムの重要な部品であるベーマイトの需要が大幅に増加する見込みです。これらの産業が拡大を続ける中、電池の性能と安全性を高める独自の特性により、ベーマイトのニーズは急増すると予想されます。

ベーマイト需要の主な要因

- 電池性能の向上:ベーマイトの高い熱安定性と化学的不活性は、バッテリーのダイアフラムに理想的な材料であり、バッテリーの長寿命化と安全性の向上を実現します。

- エネルギー貯蔵ソリューション:エネルギー貯蔵市場の急速な成長、特にグリッドスケールの貯蔵システムでは、効率的で信頼性の高いエネルギー貯蔵を確保するために、ベーマイトのような高度な材料が必要とされています。

- 持続可能なモビリティ:電気自動車(EV)へのシフトは、ベーマイトの需要を喚起する大きなきっかけとなっています。政府と自動車メーカーがEVインフラに多額の投資を行っているため、ベーマイト市場は大幅な成長を遂げることになる。

市場予測

| 市場セクター | 現在の需要(2022年) | 予測需要 (2025) | 成長率(CAGR) |

|---|---|---|---|

| 新エネルギー自動車 | 15,000トン | 35,000トン | 32% |

| エネルギー貯蔵システム | 10,000 トン | 25,000トン | 35% |

| 合計 | 25,000トン | 60,000トン | 33% |

上表は、主要セクターにおけるベーマイト需要の成長予測を示しており、出現しつつある広範な市場空間を浮き彫りにしている。この成長は、この材料がますます浸透していることを示すだけでなく、進化するエネルギー情勢において重要な役割を担っていることも強調している。

まとめると、新エネルギー自動車とエネルギー貯蔵システムの市場拡大に牽引され、ベーマイトの将来的な市場可能性は広大である。これらの産業が革新と拡大を続ける中、ベーマイトはますます重要な役割を果たすようになり、成長と発展の大きな機会を提供します。

その他の重要な市場

汎用性の高い先端セラミック粉末であるベーマイトは、その用途を主要市場以外にも広げ、様々な産業で大きく貢献しています。特に、以下の製造に使用されている。 吸着剤 高表面積と化学的安定性を活かして気体や液体を浄化する。整形外科分野では 整形外科 ベーマイトは生体適合性材料の開発に役立ち、インプラントの耐久性と性能を向上させる。

歯科分野では 歯科 歯科用セラミックの製造に不可欠であり、優れた審美性と機械的特性を提供します。生体医学 生物医学 での使用も同様に深く、薬物送達システムや組織工学の足場における主要成分として機能します。さらに、ボエマイトは以下の製造にも利用されている。 高性能銅被覆ボード 電子機器の小型化と効率化に貢献する。

さらに、ベーマイトは以下の原料としても機能する。 触媒や試薬の原料として 化学合成や環境保護プロセスにおいて重要な役割を果たしています。このような多様な用途により、ボエマイトはさまざまな分野の技術の進歩において極めて重要な役割を果たしています。

窒化アルミニウム

熱放散に最適

窒化アルミニウム(AlN)は、その卓越した熱伝導性で際立っており、ハイパワー、高リード、大型チップパッケージング基板に不可欠な特性となっています。この高度なセラミック材料は効率的に熱を放散し、過酷な動作条件下での電子部品の安定性と寿命を保証します。

半導体技術の領域では、AlNの熱伝導率は他の多くの材料を凌駕しており、高性能チップを支える基板として好まれています。これらの基板内で低温を維持する能力は、熱劣化を防ぎ、最適な性能を確保するために極めて重要です。

さらに、AlNは、GaN、AlGaN、AlNエピタキシャル層など、さまざまな半導体材料と互換性があるため、その有用性がさらに高まります。これらの組み合わせは、次世代電子デバイスの開発に不可欠な、優れた熱的整合性と化学的適合性を提供します。

まとめると、窒化アルミニウムの卓越した熱伝導性と半導体材料との相溶性は、高性能エレクトロニクスの絶え間ない進化を支える先端チップパッケージング基板の理想的な材料として位置づけられている。

半導体材料との互換性

窒化アルミニウム(AlN)結晶は、GaN、AlGaN、およびAlN材料のエピタキシャル成長用の優れた基板として機能します。この互換性は、優れた熱的整合性と化学的親和性に根ざしており、半導体デバイスの性能と信頼性を大幅に向上させます。

AlN基板の熱整合特性は、エピタキシャル層の格子定数が基板の格子定数と密接に整合し、欠陥や転位を最小限に抑えることを保証する。この整列は、半導体層の構造的完全性と電子特性を維持するために極めて重要である。

さらに、AlNとこれらの半導体材料との化学的適合性により、安定かつ均一な成長プロセスが可能になる。この安定性は、特に電気通信やパワーエレクトロニクス産業のような高周波・高出力動作を必要とするアプリケーションにおいて、高品質なデバイスの製造に不可欠です。

まとめると、AlNのユニークな特性は、半導体産業において不可欠な材料であり、高度な電子デバイスのための強固な基盤を提供します。

環境および健康上の利点

窒化アルミニウム(AlN)は、その卓越した熱伝導性だけでなく、環境および健康上の利点でも際立っています。無毒性材料であるAlNは、人の健康や環境に害を及ぼさないため、安全性と持続可能性が最優先される用途に最適です。この特性は、材料が効果的であると同時に無害でなければならない電子デバイスの領域で特に重要です。

さらに、AlNの環境への配慮は、その無害性だけにとどまりません。デバイスの耐久性と効率を高めることで、電子廃棄物の削減に貢献する。熱放散を促進することで、AlNベースの基板は電子部品の寿命を延ばし、交換頻度とそれに伴う環境への影響を低減することができます。

直接的な利点に加え、AlNは、よりエネルギー効率の高い技術の開発を可能にすることで、より広範な環境目標もサポートしています。例えば、自動車産業では、AlNで強化されたエレクトロニクスが電気自動車の効率化に貢献し、全体的なカーボンフットプリントの削減に貢献します。このように、健康と環境の持続可能性の両面からAlNは、エレクトロニクスの未来とその先の未来における重要な材料としての役割を担っています。

窒化ケイ素

多目的セラミック材料

高性能セラミック材料である窒化ケイ素は、その卓越した機械的および熱的特性により、様々な産業分野で幅広い用途が見出されています。最も注目すべき用途のひとつは高速旋削工具で、その硬度と耐摩耗性により、強靭な材料の精密加工が可能になります。自動車分野では、窒化ケイ素はエンジンワイパーブレードやベアリングに不可欠であり、高ストレス環境での耐久性と性能を高めている。

航空宇宙工学の分野では、窒化ケイ素はその高温耐性と低熱膨張を利用して、ガスタービンのガイドブレードやタービンブレードに利用されています。さらに、電子機器では放熱基板として機能し、ハイパワーデバイスの効率的な熱管理を促進します。窒化ケイ素は、このような工業用途のほか、医療分野でもバイオセラミックスとして重要な役割を果たしており、インプラントや人工関節に生体適合性と強度を提供しています。

| 応用分野 | 産業分野 | 利点 |

|---|---|---|

| 高速旋削工具 | 製造 | 高硬度、耐摩耗性 |

| エンジンワイパーブレード | 自動車用 | 耐久性の向上、応力下での性能 |

| ベアリング | 各種 | 高負荷容量、低摩擦 |

| ガスタービンブレード | 航空宇宙 | 高温耐性、低熱膨張 |

| 放熱基板 | エレクトロニクス | 効率的な熱管理 |

| バイオセラミックス | 医療用 | 生体適合性、インプラントの強度 |

この汎用性の高い素材は、エンジニアリングとテクノロジーの可能性の限界を押し広げ続けており、多くの産業の発展における重要な役割を担っている。

有望なレドーム

窒化ケイ素は、その卓越した機械的特性、熱安定性、低誘電率、強固な耐アブレーション特性により、レドーム用材料として最も有望視されています。これらの特性により、過酷な条件下での耐久性と性能が最重要視される用途に理想的な選択肢となります。

レドーム用窒化ケイ素の主な利点

- 機械的強度:窒化ケイ素は優れた機械的強度を示し、構造的完全性を損なうことなく高圧や衝撃に耐えることができます。

- 熱安定性:優れた熱安定性により、過酷な気象条件にさらされるレドームにとって重要な高温環境下でも安定した機能を維持します。

- 低誘電率:窒化ケイ素の低誘電率は、信号損失を低減し、電磁波伝送の効率を向上させるため、レーダー用途に非常に適しています。

- 耐アブレーション性:窒化ケイ素のアブレーション(高速粒子による磨耗)に対する耐性は、高ストレス環境での長期耐久性と性能を保証します。

これらの特性により、窒化ケイ素はレドーム材料の最有力候補として位置づけられ、重要な航空宇宙および防衛用途での性能向上と長寿命が期待されています。

主な用途

窒化ケイ素は、ベアリングボール材料および放熱基板材料としての用途で大きな注目を集めている。その様々な用途の中でも、ベアリングボールは最も広く利用されている製品として際立っています。高硬度、耐摩耗性、熱安定性などの機械的特性に優れ、精密性や耐久性が要求される産業分野では欠かせない材料となっています。

ベアリングボール以外にも、窒化ケイ素はさまざまな重要部品に採用されている。例えば、エンジンのワイパーブレード、ガスタービンのガイドブレード、タービンブレードなどに使用されており、高い強度と耐熱衝撃性が特に有利に働いています。さらに、窒化ケイ素の放熱基板としての役割は、効率的な熱管理が最適な性能と長寿命に不可欠な電子機器において極めて重要です。

| 用途 | 利点 |

|---|---|

| ベアリングボール | 高硬度、耐摩耗性、優れた熱安定性 |

| エンジンワイパーブレード | 高強度、耐熱衝撃性 |

| ガスタービンのガイドブレード | 高強度、耐熱衝撃性 |

| タービンブレード | 高強度、耐熱衝撃性 |

| 放熱基板 | 効率的な熱管理、最適性能、長寿命 |

窒化ケイ素の多用途性と優れた機械的特性は、ハイテク産業で選択される材料となっており、幅広い用途で信頼性と性能を保証します。

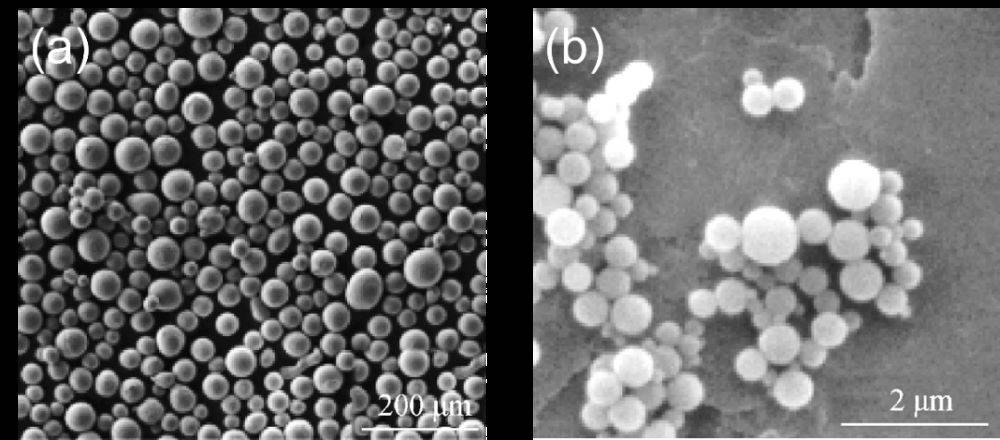

球状アルミナ

熱伝導性粉末の主流

球状アルミナは、ハイエンド熱伝導性分野で最も普及している熱伝導性粉末としての地位を固めている。この優位性はいくつかの重要な要因によるものである:

- 高い熱伝導率:球状アルミナは熱伝導に優れており、効率的な熱管理を必要とする用途に不可欠です。

- 高い充填係数:材料内に高密度に充填できるため、スペースを犠牲にすることなく最適な性能を発揮します。

- 優れた移動性:加工時の流動性が高いため、均一な分散が可能で、熱伝導性材料全体の効果を高めます。

- 成熟した技術:球状アルミナに投資された広範な研究開発により、堅牢で信頼性の高い製造プロセスが実現しました。

これらの特徴を総合すると、球状アルミナは、エレクトロニクスから新エネルギー自動車に至るまで、優れた熱伝導性を必要とする産業にとって最適な選択肢となる。

市場の成長と将来展望

球状アルミナ熱伝導性粉末の世界市場は大幅な拡大が見込まれており、2025年の市場規模は54.0億元になると予測されている。この成長は、28.2%という堅調な年平均成長率(CAGR)に支えられており、さまざまな産業で高度な熱管理ソリューションに対する需要が高まっていることを反映している。

市場成長の主な要因

-

技術の進歩:製造プロセスの継続的な改善と、より高性能な球状アルミナ粉末の開発が市場拡大の原動力となっている。これらの進歩により、材料の熱伝導性と加工効率が向上し、ハイエンド用途に魅力的な材料となっている。

-

エレクトロニクス分野の需要増加:エレクトロニクス分野、特にスマートフォン、タブレット端末、高性能コンピューティングデバイスは、球状アルミナの主要な消費者である。これらのデバイスにおける効率的な放熱の必要性が、熱伝導性粉末の需要に拍車をかけている。

-

新エネルギー自動車(NEV):急成長するNEV市場も重要な原動力である。球状アルミナは、バッテリー、電子制御ユニット、モーターの熱管理システムに広く使用され、電気自動車の最適性能と安全性を確保している。

-

航空宇宙と防衛:航空宇宙・防衛分野では、優れた熱特性を持つ球状アルミナの採用が増加している。熱シールドから熱保護システムまで幅広い用途があり、市場の成長に貢献している。

将来の展望

球状アルミナ市場の将来は有望であり、いくつかの新たなトレンドがその軌道を形成すると予想される:

- 材料科学の革新:継続的な研究開発によって新たな配合や用途が生まれ、市場の成長をさらに押し上げる可能性が高い。

- 持続可能性への取り組み:環境問題への関心の高まりが、メーカーに環境に優しい製造方法の採用を促しており、より持続可能な球状アルミナ製品の開発につながる可能性がある。

- グローバル展開:アジア太平洋地域の新興市場、特に中国とインドは、急速な工業化と先端材料への投資の増加により、大きな成長が見込まれている。

まとめると、球状アルミナ熱伝導性粉末市場は、技術の進歩、主要分野での需要の高まり、世界的な市場の拡大により、大幅な成長が見込まれる。

新エネルギー自動車への応用

球状アルミナは、新エネルギー自動車(NEV)の熱管理システムの強化において重要な役割を果たしている。具体的には、NEVのバッテリー、電子制御ユニット(ECU)、モーター用の熱伝導材料やサーマルインターフェイス材料(TIM)に組み込まれている。これらの用途は、最適な動作温度を維持し、これらの重要部品の寿命と効率を確保するために不可欠です。

NEV用バッテリーでは、球状アルミナ入り熱伝導性材料が効率的な熱放散を促進し、熱暴走を防止して安全な運転を保証します。球状アルミナは熱伝導率が高いため、バッテリーの動作中に発生する熱を効果的に管理し、バッテリーの寿命を延ばし、性能を向上させます。

ECUでは、球状アルミナがTIMに使用され、電子部品とヒートシンク間のギャップを埋めることで、迅速かつ効率的な熱伝達を実現している。これは、動作中に大きな熱を発生するECUでは特に重要です。球状アルミナを使用することで、過熱のリスクを最小限に抑え、ECUの信頼性と性能を向上させることができる。

同様に、NEVモーターでは、高速運転中に発生する熱を管理するために、熱伝導性材料に球状アルミナが採用されている。これにより、モーターの効率を維持し、過熱による機械的故障のリスクを低減することができる。これらの用途における球状アルミナの使用は、新エネルギー車の全体的な設計と性能におけるその重要性を強調している。

関連製品

- 高機能エンジニアリングファインセラミックス 窒化アルミニウム(AlN)セラミックシート

- 産業用途向けエンジニアリング先進ファインアルミナ Al2O3 セラミックロッド絶縁体

- エンジニアリング先進ファインセラミックス用高純度アルミナ造粒粉末

- 高温耐性と絶縁性を備えたエンジニアリング先進ファインセラミックス用高品質アルミナセラミックス製ねじ

- 高度エンジニアリングファインセラミックス低温アルミナ造粒粉末