等方性黒鉛の製造は、超微細粒で非常に均一な材料を作り出すために設計された、多段階の高温プロセスです。まず、粉砕されたコークスとピッチバインダーを混合し、次に冷間等方圧プレス(CIP)で全方向から均等な圧力で圧縮します。この「グリーン」ブロックは、最終的な結晶構造を得るために、最大2800℃の黒鉛化段階で一連の極端な熱処理を受けます。

等方性製造プロセスの複雑さは欠陥ではありません。それは、この材料が優れた均一な特性を持つ正確な理由です。この方法は、他の黒鉛に見られる方向性のある結晶粒を排除することにより、比類のない等方性と純度を持つ材料を生成し、従来の黒鉛では不十分な用途に不可欠なものとなっています。

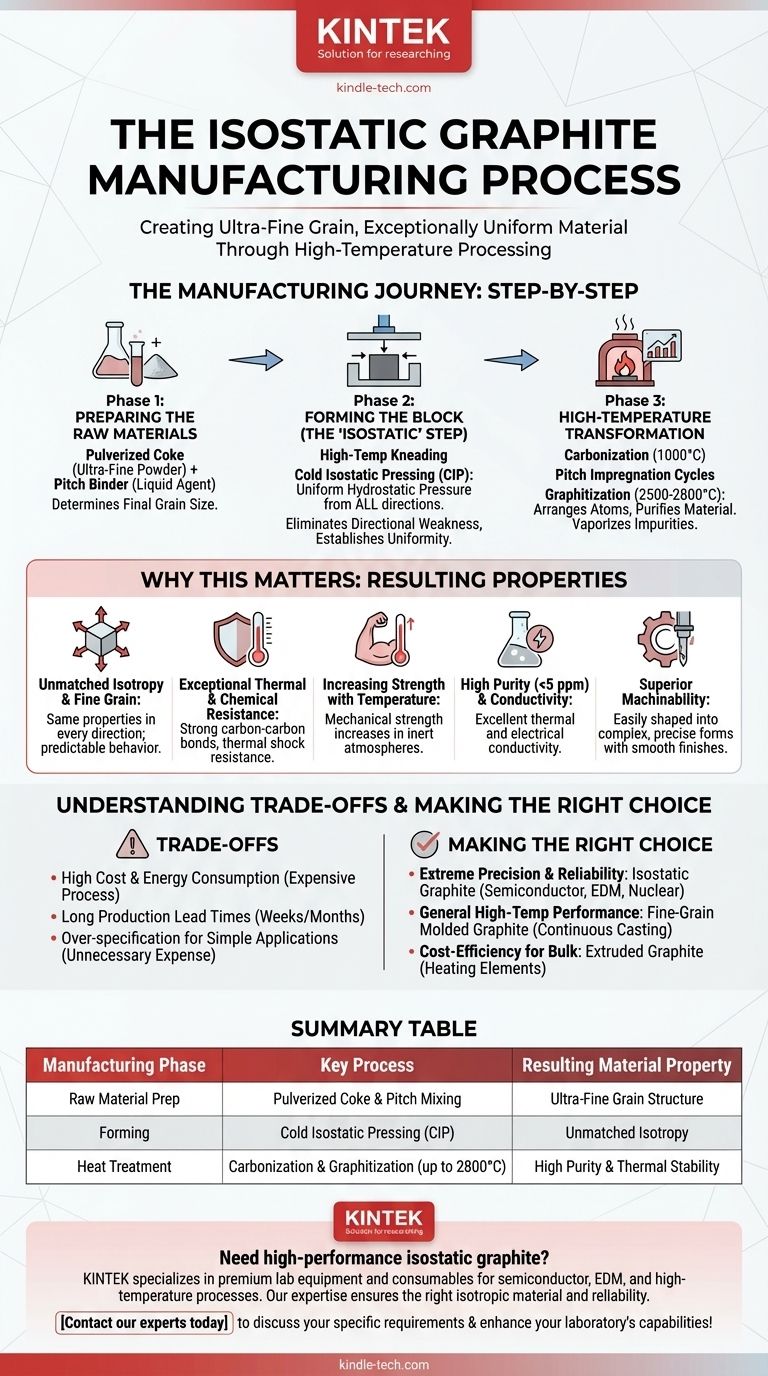

製造工程、ステップバイステップ

生の粉末から完成した高純度ブロックまでの道のりは、意図的かつ制御されています。各段階が材料の最終的な特性に直接貢献します。

フェーズ1:原材料の準備

等方性黒鉛の基礎は、2つの主要な構成要素の精密な混合物です。

1つ目は、高品質のコークスで、通常は石油または石炭から得られ、超微細な粉末に粉砕されます。黒鉛の最終的な粒径は、この初期段階で決定されます。

2つ目はピッチで、コークス化石炭の副産物である密度の高い黒い液体です。このピッチは、その後の成形プロセス中にコークス粒子を結合させるバインダーとして機能します。

フェーズ2:ブロックの成形(「等方性」ステップ)

これはプロセスの決定的な段階であり、材料の独自の均一性が確立されます。

粉砕されたコークスと液体ピッチバインダーは、高温の混練プロセスで結合され、均質なペースト状の混合物が作成されます。

この混合物は、柔軟な型に入れられ、冷間等方圧プレス(CIP)にかけられます。一方向または二方向から圧力を加える押出成形やダイ成形とは異なり、CIPはあらゆる方向から強力で均一な静水圧をかけます。これにより、コークス粒子が優先的な配向なしに圧縮され、固有の方向性のある弱点が排除されます。

フェーズ3:高温変換

プレスされた「グリーン」ブロックはまだ黒鉛ではありません。その構造を変換するために、一連の激しい、エネルギーを消費する熱処理を受けなければなりません。

まず、ブロックは1000℃程度の温度で炭化または「焼成」されます。これにより、ピッチバインダーが固体炭素に変換され、硬くて多孔質の炭素ブロックが生成されます。

密度を高め、最終的な特性を改善するために、ブロックは1回以上のピッチ含浸サイクルを受けることがあります。ピッチに浸漬され、細孔が満たされた後、再焼成されます。

最後に、ブロックは黒鉛化炉で極端な温度、通常は2500℃から2800℃まで加熱されます。このステップは、アモルファス炭素原子を黒鉛の秩序だった結晶構造に再配置するために必要なエネルギーを提供します。この段階では、ほとんどの不純物がこれらの温度で蒸発するため、材料も精製されます。

このプロセスが重要な理由:結果として得られる特性

この精巧な製造プロセスは、一連のユニークで非常に望ましい材料特性を直接生み出します。

比類のない等方性と微細粒

CIP法は、最終的なブロックが等方性特性を持つことを保証します。つまり、その機械的および熱的特性(強度や熱膨張など)がすべての方向で同じであることを意味します。これは、超微細粒と相まって、その挙動を非常に予測可能で信頼性の高いものにします。

優れた耐熱性と耐薬品性

黒鉛化中に形成される強力な炭素-炭素結合は、材料に非常に高い熱安定性と優れた耐薬品性を与えます。また、優れた耐熱衝撃性も示し、急激な温度変化にもひび割れなく耐えます。

温度上昇に伴う強度増加

金属とは異なり、黒鉛の主な特徴は、不活性雰囲気下で温度が上昇すると機械的強度が増加することです。これにより、炉やロケットノズルなどの高温環境に最適です。

高純度と導電性

高温黒鉛化プロセスは、ほとんどすべての不純物を除去し、5ppm(百万分の5)未満の純度の黒鉛を製造することを可能にします。秩序だった結晶構造は、高い熱伝導率と電気伝導率も保証します。

優れた加工性

均一な微細粒構造により、等方性黒鉛は、半導体や放電加工(EDM)用途に不可欠な、微細なディテールと滑らかな表面仕上げを持つ複雑で精密な形状に容易に機械加工できます。

トレードオフを理解する

その特性は例外的ですが、等方性黒鉛がすべての問題の解決策となるわけではありません。その限界を理解することが、情報に基づいた意思決定を行う上で重要です。

高コストとエネルギー消費

多段階プロセス、特に黒鉛化に必要な極めて高い温度は、非常にエネルギー集約的で時間がかかります。これにより、等方性黒鉛は、押出成形または振動成形黒鉛よりも著しく高価になります。

長い生産リードタイム

複数の加熱、冷却、含浸サイクルがあるため、生産プロセスは開始から終了まで数週間、あるいは数ヶ月かかることがあります。これは、プロジェクト計画とサプライチェーン管理にとって重要な要素です。

単純な用途への過剰な仕様

完璧な等方性、極端な純度、または超微細粒を必要としない用途では、等方性黒鉛を使用することは不必要な費用となる可能性があります。鋳造金型や炉電極などの用途では、より単純で安価なグレードの黒鉛で十分な性能を発揮することがよくあります。

あなたのアプリケーションに最適な選択をする

適切なグレードの黒鉛を選択するには、性能要件と予算、プロジェクトのタイムラインのバランスを取る必要があります。

- 極端な精度と信頼性が最優先事項である場合: 等方性黒鉛は、半導体るつぼ、原子炉部品、または微細な放電加工(EDM)などの要求の厳しい用途に最適な選択肢です。

- 一般的な高温性能が最優先事項である場合: 連続鋳造ダイや炉治具などの用途では、他の微細粒成形黒鉛がコストと性能のより良いバランスを提供する可能性があります。

- バルク部品のコスト効率が最優先事項である場合: 方向性特性を持つが製造コストがはるかに安い押出成形黒鉛は、発熱体や電極などのアイテムにとってより実用的なソリューションとなるでしょう。

製造プロセスと材料特性の直接的な関連性を理解することで、プロジェクトが本当に必要とする正確な黒鉛を自信を持って選択できます。

要約表:

| 製造段階 | 主要プロセス | 結果として得られる材料特性 |

|---|---|---|

| 原材料準備 | 粉砕コークスとピッチの混合 | 超微細粒構造 |

| 成形 | 冷間等方圧プレス(CIP) | 比類のない等方性 |

| 熱処理 | 炭化と黒鉛化(最大2800℃) | 高純度と熱安定性 |

精密な用途に高性能な等方性黒鉛が必要ですか? KINTEKは、半導体、EDM、および高温プロセス向けの高純度黒鉛ソリューションを含む、プレミアムな実験装置と消耗品を専門としています。当社の専門知識により、お客様のプロジェクトが要求する等方性特性と信頼性を備えた適切な材料を確実に入手できます。今すぐ当社の専門家にお問い合わせください。お客様の特定の要件について話し合い、KINTEKがお客様のラボの能力をどのように向上させることができるかを発見してください!

ビジュアルガイド