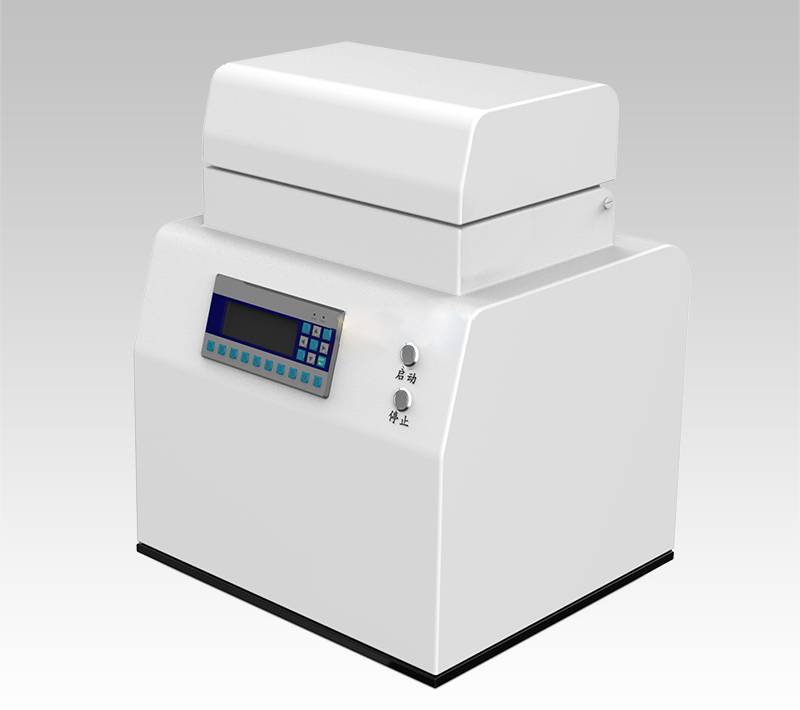

凍結組織破砕機の紹介

定義と重要性

凍結組織破砕機は、交差汚染を防ぐためにサンプルを粉砕する際に重要な役割を果たす、研究室環境において不可欠なツールです。従来の方法とは異なり、これらの粉砕機は大規模な処理を効率的に処理できるように設計されており、粉砕プロセスを通じてサンプルの完全性が維持されることを保証します。この機能は、サンプルの純度が最も重要なバイオテクノロジーや製薬などの分野で特に重要です。

凍結組織破砕機の重要性は、単なる効率性だけにとどまりません。従来の粉砕方法における一般的な課題であるコンタミネーションのリスクを最小限に抑えるように設計されています。高度な技術と素材を採用することで、これらの粉砕機は、しばしば面倒でミスを起こしやすいサンプル前処理プロセスに対する信頼性の高いソリューションを提供します。これは検査結果の精度を高めるだけでなく、ワークフローを合理化し、より管理しやすく、より時間のかからないものにする。

さらに、凍結組織破砕機の多用途性は注目に値する。軟組織から硬い骨まで、さまざまな種類のサンプルに合わせて調整することができ、それぞれの材料に最適な粉砕プロセスを確保することができる。この適応性の高さが、さまざまな科学分野で広く採用されている重要な要因である。

まとめると、凍結組織破砕機は単なる道具ではなく、現代の研究室業務に不可欠なコンポーネントであり、従来の方法と、汚染のない精密なサンプル処理の必要性とのギャップを埋めるものである。凍結組織破砕機の開発と応用は、科学研究に対する要求の高まりと、研究室での手順におけるより高い基準の追求を反映し、進化し続けている。

適切な破砕機の選択

適切な凍結組織破砕機を選択するには、様々な操作パラメータと材料固有の要件を考慮した多面的なアプローチが必要です。凍結組織破砕機は 振動モード は、その効率と効果を決定する上で極めて重要な役割を果たす。破砕機は、垂直、水平、三次元など、複数の次元で振動することができ、それぞれが特定の用途に合わせた明確な利点を提供する。例えば、垂直揺動はデリケートなサンプルに最適で、三次元揺動は頑丈な材料に適した、より徹底的な粉砕プロセスを提供します。

また 粉砕方法 も重要な要素です。例えば 遊星ボールミル 遊星ボールミル、モルタルミル、ナイフミル、ディスクミル、ジョークラッシャーなど、さまざまなタイプの粉砕機があり、さまざまな粉砕ニーズに対応している。 遊星ボールミル は、高いエネルギー効率と微粉砕能力で知られ、研究用途に適しています。逆に、ナイフミルはスピードと簡便性から、バルクサンプルの処理に実用的です。

さらに 処理する試料に特有の要件 も見逃せません。硬度、密度、化学的性質が異なる材料は、異なる粉砕アプローチが必要となる。例えば、軟組織は過度の劣化を避けるために穏やかな粉砕方法が必要かもしれないが、硬組織はより積極的な粉砕技術が有効である。したがって、試料の完全性と処理効率を最適化する粉砕機を選択するためには、試料の特性を理解することが不可欠である。

まとめると、凍結組織破砕機の選択は、振動モード、粉砕方法、材料固有のニーズのバランスをとりながら、実験室でのサンプル前処理で最良の結果を得るための微妙なプロセスである。

歴史的発展

初期の革新

実験室用粉砕機の進化は、1923年にRetschが最初の乳鉢型粉砕機を開発したことから始まった。この先駆的な技術革新は、より高度な粉砕技術の基礎を築きました。1962年、FRITSCHは 遊星ボールミル これは、粉砕プロセスの精度と効率に革命をもたらす重要な進歩でした。この革新的な技術は、その後、タカラトミーやMPなどの企業も同様の技術を導入しています。

これらの初期の開発は、実験室用粉砕機の状況を形成する上で極めて重要なものであった。遊星ボールミル 遊星ボールミル 例えば遊星ボールミルの導入は、より制御された効率的な粉砕を可能にし、デリケートな試料の取り扱いやコンタミネーションを最小限に抑えるのに特に有益であった。この技術革新の時代は、この分野における更なる進歩の舞台となり、科学研究や産業用途の進化するニーズに応えるため、粉砕技術の絶え間ない改良を推進した。

国内外の動向

輸入品の冷凍組織破砕機には高額な値札が付いていることが多いが、国内メーカーは近年大きな進歩を遂げている。国産凍結組織破砕機の品質と技術的進歩は急速に向上し、操作の細部における差を効果的に縮め、ユーザー・エクスペリエンスを向上させている。この変化は、特に以下の分野で顕著である:

-

作業効率:作業効率:国産クラッシャーは現在、海外のクラッシャーに匹敵する作業効率を提供している。精密制御、自動化されたプロセス、ユーザーフレンドリーなインターフェイスなどの機能が標準となり、ユーザーは大規模なトレーニングや専門的な知識を必要とすることなく、同レベルの性能を達成できるようになった。

-

カスタマイズとサポート:国内オプションの主な利点の1つは、特定のニーズに合わせて粉砕機をカスタマイズできることです。メーカーは、特殊な振動モードや粉砕方法など、独自の要件に対応するカスタマイズソリューションを提供できる。さらに、現地でのサポートやメンテナンスサービスも容易に利用できるため、ダウンタイムを減らし、継続的な稼働を保証することができる。

-

費用対効果:国産粉砕機の初期投資と継続的なメンテナンスコストは、一般的に輸入モデルよりも低い。この費用対効果により、研究所や研究機関は、機器の品質や性能に妥協することなく、より効率的に予算を配分することができる。

-

技術統合:国産粉砕機は現在、IoT接続、リアルタイムモニタリング、データ分析などの先進技術を組み込んでいる。これらの機能は、作業効率を高めるだけでなく、粉砕プロセスに関する貴重な洞察を提供し、ユーザーがワークフローを最適化し、より良い結果を達成することを可能にする。

まとめると、国産凍結組織破砕機の急速な進歩により、多くの研究所や研究機関にとって、凍結組織破砕機は実行可能で魅力的な選択肢となった。同等の性能、より高いカスタマイズ性、費用対効果を提供することで、これらの粉砕機は、組織粉砕プロセスの強化を目指す人々にとって、ますます好ましい選択肢となりつつある。

分類と原理

振動モード

粉砕機にはさまざまな振動モードがあり、それぞれの振動モードは特定の用途や材料特性に合わせて調整されます。これらの振動モードは、垂直振動、水平振動、三次元振動に大別され、それぞれに明確な利点があります。

- 垂直振動:このモードは、精密で制御された粉砕が必要な材料に特に効果的です。材料ロスを最小限に抑え、均一性が重要なデリケートな試料に最適です。

- 水平揺動:バルク処理に最適なこのモードは、スループットが高く、大量の試料を効率的に処理できます。微細な精度よりもスピードと量が重視される産業でよく使用されます。

- 三次元オシレーション:縦揺動と横揺動の両方の利点を併せ持ち、より包括的な研削作用を提供する高度なモードです。柔らかいものから硬いものまで、幅広い素材に適しており、特に均質な粉砕を実現するのに効果的です。

各振動モードには独自の用途があるため、処理する材料固有の要件に基づいて適切な粉砕機を選択することが不可欠です。

粉砕方法

粉砕方法は、凍結組織サンプルを効果的に処理するために極めて重要であり、クロスコンタミネーションを引き起こすことなく微粉砕することを保証します。粉砕方法の選択は、処理される材料の具体的な要件、希望する粒子径、作業に必要な効率によって決まります。

この分野では、いくつかの一般的な粉砕方法が採用されており、それぞれに独自の利点と用途がある。 遊星ボールミル は、その高いエネルギー効率で知られ、高度の細かさを必要とする材料に特に有用です。遠心力を利用して粉砕ボールを加速させ、そのボールが試料に衝突することで、微細で均一な粒子径が得られます。

モルタルミル も、特に穏やかな粉砕プロセスを必要とする試料によく使われます。この粉砕機は、乳鉢と乳棒のような機構で試料を粉砕するため、攻撃的な方法では損傷する可能性のあるデリケートな試料に最適です。

より攻撃的なアプローチが必要な材料には ナイフミル および ディスクミル がよく使われる。ナイフミルは鋭利な刃で試料を細かく切断し、ディスクミルは回転する円盤で試料を粉砕する。どちらの方法も硬い素材や繊維質の素材に効果的である。

最後に ジョークラッシャー は、大きな試料の初期粉砕に使用される。特に、ボールミルやモルタルミルなどでさらに処理する前に、試料を小さくするのに有効である。

まとめると、適切な粉砕方法を選択することは、組織加工において望ましい結果を得るために不可欠である。それぞれの方法には長所があり、さまざまな種類の材料や加工ニーズに適している。

粉砕ボールの選択

材料の検討

粉砕ボールの材質選択は、粉砕プロセスの効率と装置の寿命の両方に大きく影響する重要な要素です。それぞれの材料は、処理される組織サンプルの特定の要件に応じて、粉砕性能を高めたり、妨げたりすることができるユニークな特性を提供します。

一般的な粉砕ボールの材質は以下の通りです:

-

ステンレス鋼:耐久性と耐腐食性で知られるステンレス鋼のボールは汎用性があり、様々な種類の組織に対応できる。しかし、金属コンタミネーションを引き起こす可能性があり、一部の繊細なアプリケーションでは懸念される。

-

酸化アルミニウム:非常に硬く、耐摩耗性に優れているため、衝撃性の高い研削に最適です。また、非反応性であり、コンタミネーションのリスクを低減します。しかし、高価であることが制限要因となる場合があります。

-

瑪瑙:アゲートボールは優れた硬度と低い摩擦係数を持ち、試料の損失を最小限に抑えながら効率的な粉砕を可能にします。コンタミネーションを最小限に抑えなければならないデリケートな試料に特に適しています。

-

カーバイド:超硬ボールは耐久性に優れ、高圧の粉砕環境にも耐えることができます。高い精度が要求され、組織試料の硬度が重要な用途によく使用されます。

| 材質 | 利点 | 欠点 |

|---|---|---|

| ステンレス鋼 | 耐久性、耐食性、汎用性 | 金属汚染の可能性 |

| 酸化アルミニウム | 硬質、耐摩耗性、非反応性 | 高コスト |

| メノウ | 硬質、低摩擦、サンプルの損失最小 | 脆い、過酷な条件下では欠けることがある |

| カーバイド | 耐久性に優れ、高圧環境にも対応 | 高価で、用途によっては硬すぎることもある。 |

材料の選択は、組織サンプルの具体的なニーズ、望まれる粉砕効率、潜在的な汚染に対する許容範囲によって導かれるべきである。各材料にはそれぞれ利点と欠点があり、粉砕効果と装置の寿命の両方を最適化するためには、その選択プロセスが極めて重要である。

ボールの直径と数

粉砕ボールの直径と個数は、粉砕効果と全体的な生産効率に大きく影響する重要なパラメータです。これらのパラメータは、処理される材料の特性や要求される結果に基づいて慎重に選択されなければなりません。

次の表は、異なるボール直径と個数による典型的な影響を概説したものです:

| ボール直径 (mm) | ボール数 | 粉砕効果 | 生産効率 |

|---|---|---|---|

| 10 | 100 | 中程度 | 高い |

| 20 | 50 | 高 | 中程度 |

| 30 | 25 | 非常に高い | 低い |

一般に、大きなボールは質量と運動エネルギーが大きいため、より強力な粉砕効果が得られるが、ミル内の容積が大きくなるため、全体的な粉砕効率が低下する可能性がある。逆に小さいボールは、単位時間当たりの衝突回数を増やすことで、より高い粉砕効率を実現するが、大きいボールと同レベルの粉砕力が得られない場合がある。

したがって、ボールの直径と個数の最適な組み合わせは、材料の硬さ、壊れやすさ、最終製品の要求される細かさを考慮し、慎重に実験して決定する必要があります。このバランスにより、粉砕プロセスが効果的かつ効率的になり、実験室または工業用途の特定の要件を満たすことができます。

正しい粉砕機の選択

振動ボールミルと遊星ボールミルの比較

凍結組織試料の粉砕には、振動ボールミルと遊星ボールミルの2種類の粉砕機があります。 遊星ボールミル .振動ボールミルと遊星ボールミルです。両者にはそれぞれ独自の特徴と運転効率がありますが、エネルギー利用や粉砕の成果という点では大きく異なります。

振動ボールミルは、短時間に大量の粉砕エネルギーを生成できることで知られています。粉砕室内で粉砕ボールが高速で振動するため、材料を迅速かつ効率的に処理できます。この効率は、大量の試料を扱う場合や時間が重要な要素である場合に特に有利です。振動ボールミルの粉砕効果は、その速さにもかかわ らず、遊星ボールミルの粉砕効果に匹敵します。 遊星ボールミル 振動ボールミルの粉砕効果は遊星ボールミルの粉砕効果に匹敵することが多く、多くのラボアプリケーションで有効な選択肢となります。

一方 遊星ボールミル は、より制御された微妙な粉砕プロセスを提供します。遊星ボールミルは、遊星運動の原理を利用したもので、粉砕ボールが高エネルギーの複雑な軌道を描きながら移動します。その結果、より均一で完全な粉砕効果が得られ、デリケートな材料や繊細な材料に特に有効です。一方 遊星ボールミル は、所望の粉砕結果を得るために、より多くの時間を必要とするかもしれませんが、粉砕プロセスを正確に制御することにより、最終製品の品質は、しばしば優れています。

| 特徴 | 振動ボールミル | 遊星ボールミル |

|---|---|---|

| 粉砕エネルギー | 高い | 制御 |

| 時間効率 | 高い | 中程度 |

| 研削効果 | 同等 | 優れている |

| 用途適合性 | バルク処理 | デリケートな材料 |

まとめると、振動ボールミルはスピードとエネルギー効率に優れています、 遊星ボールミル 遊星ボールミルは、より精密に制御された粉砕プロセスを提供するため、より高い精度が要求される材料に最適です。この2種類の粉砕機のどちらを選択するかは、最終的にはラボの具体的な要件と処理材料の性質によって決まります。

操作上の考慮点

凍結組織破砕機を選択する際には、各ブランド特有の操作上のニュアンスを理解することが不可欠です。これらの違いは、粉砕プロセスの効率と効果に大きな影響を与える可能性がある。例えば、振動モードは、垂直、水平、三次元のいずれであっても、お客様のニーズに最も適した試料前処理のタイプを決定することができます。同様に、粉砕方法は、次のようなものがある。 遊星ボールミル から乳鉢ミルまで、粉砕方法は試料の最終的な粒子径と均質性に影響します。

お客様のニーズに最適な粉砕機を選ぶには、カスタマーレビューを読むだけでなく、実際に試用することをお勧めします。レビューは、クラッシャーの使用感、耐久性、全体的な性能についての洞察を与えてくれます。しかし、個人的な試用では、機器の適合性を直接評価することができ、研究室や研究環境特有の要求を確実に満たすことができます。この実践的なアプローチは、メーカーが主張することを検証するのに役立ち、選択された破砕機がお客様の業務目標とサンプル処理のニーズに合致していることを確実にします。