Constant Flow Pumps

Characteristics and Applications

Constant flow pumps exhibit a range of distinctive features that make them indispensable in various applications. These pumps are renowned for their accuracy, durability, and stability in delivering flow rates. Their design allows for continuous adjustment under higher pressure and head conditions, ensuring that the material being delivered remains isolated from external elements, thereby preventing contamination.

In terms of applications, constant flow pumps are versatile tools used for adding liquid and pumping liquid in a variety of settings. One of their notable uses is in micro-delivery for small canning processes, where precision is crucial. This capability makes them ideal for tasks requiring meticulous control over the flow of liquids, such as in laboratory settings or in the production of small-scale consumables.

| Characteristic | Description |

|---|---|

| Accuracy | High precision in flow rate delivery |

| Durability | Long-lasting performance under various conditions |

| Stability | Consistent flow rate under different pressures |

| Continuous Adjustment | Ability to adjust flow rates under higher pressures |

| Contamination Prevention | Ensures material isolation from external elements |

| Application | Description |

|---|---|

| Liquid Addition | Used for precise addition of liquids in various processes |

| Liquid Pumping | Efficiently pumps liquids in different settings |

| Micro-Delivery | Ideal for small canning processes requiring high precision |

These characteristics and applications highlight the critical role that constant flow pumps play in ensuring the accuracy and safety of liquid handling processes in laboratories and industrial settings.

Vacuum Pumps

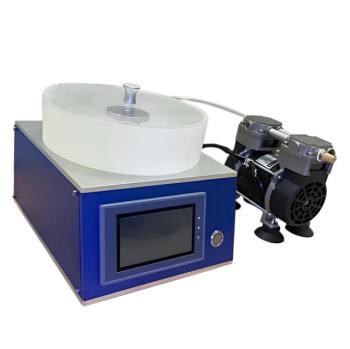

Oil-Free Vacuum Pump

An oil-free vacuum pump functions without the need for oil lubrication, relying instead on a dry lubricant to mitigate friction between its internal components. This type of pump typically includes variants such as piston, diaphragm, and scroll pumps, each designed to handle different operational demands. The core mechanism involves an eccentrically installed rotor with vanes that divide the pump chamber into multiple working chambers. These vanes serve to isolate the stator's inlet and outlet, facilitating the volumetric changes necessary to expel the inhaled gas, thereby achieving the vacuum effect.

In chemically resistant models, the internal components are often coated with Polytetrafluoroethylene (PTFE), enhancing their suitability for handling a wide range of corrosive gases. This makes oil-free vacuum pumps particularly adept in applications such as large and small-scale extraction, as well as membrane filtration. Despite their generally portable and low-maintenance nature, these pumps do come with a trade-off in terms of maximum achievable vacuum power, which tends to be weaker compared to oil-lubricated counterparts. For instance, models like the Rocker 300 and Rocker 400 are optimized for filtration applications involving non-corrosive solvents, while the Lafil 300C, Chemker 300, and Rocker 300C offer enhanced chemical resistance for broader vacuum filtration needs.

Rotary Vane Vacuum Pump

The rotary vane vacuum pump features an eccentrically mounted rotor that is tangent to the fixed surface of the stator. This rotor houses sliding vanes, which move within grooves to divide the pump chamber into several variable volumes. The gap between the vane and the pump chamber is meticulously sealed with oil, transforming it into an oil-sealed mechanical vacuum pump. This design ensures a robust and consistent vacuum pressure, typically operating below 10-3mbar, making it ideal for demanding laboratory applications such as hydraulic brake systems, freeze dryers, and mass spectrometry.

Oil plays a crucial role in this type of pump, not only for sealing but also for providing complete airtightness, effective lubrication of moving components, and facilitating good heat dissipation to keep the pump cool. Regular maintenance, including periodic oil changes (usually every 3,000 hours of operation), is essential to maintain optimal performance and to limit the possibility of wear. Despite its advantages, the use of oil-sealed pumps comes with challenges, such as dealing with toxic oil waste and the difficulty in finding replacement spare parts. Popular models like the Tanker 130 and Tanker 230 cater to different operational needs, with the former suitable for smaller applications and the latter for larger ones.

These pumps are particularly well-suited for handling solvents and watery samples that tend to boil quickly, as they excel in removing vapors before they can affect the pump's performance. This makes them a cost-effective yet high-performance choice for operators in need of a reliable vacuum solution.

Diaphragm Vacuum Pump

A diaphragm vacuum pump is a sophisticated oscillation displacement pump that belongs to the gas transfer vacuum pump family. Its design allows it to operate efficiently within the rough vacuum range, making it indispensable in environments requiring precise pressure control, such as a few millibars. This capability renders it a vital tool in chemical laboratories for pharmaceutical and medical processes, among other applications.

The operating principle of a diaphragm vacuum pump involves a diaphragm that oscillates between a pump head and the casing wall, driven by a connecting rod and an eccentric. This oscillation creates a pumping or compression chamber whose volume changes periodically, facilitating the pumping action. The valves are strategically positioned to ensure that the pumping chamber connects to the intake line during the volume increase phase and to the exhaust line during compression.

One of the standout features of a diaphragm vacuum pump is its dry compressing mechanism, which ensures that the pumping chamber remains free of oil and lubricants. This is achieved through a hermetic seal provided by the diaphragm, separating the gear chamber from the pumping chamber. Additionally, the diaphragm and valves are the only components in direct contact with the pumped medium, enhancing the pump's suitability for handling aggressive vapors and gases. By coating the diaphragm with PTFE (Teflon) and using highly fluorinated elastomers for the inlet and exhaust valves, the pump can effectively manage these challenging media, making it an excellent choice for vacuum applications in chemistry labs.

Chemical Hybrid Pump

A chemical hybrid pump is an innovative solution that integrates the functionalities of both a rotary vane pump and a chemical corrosion-resistant diaphragm pump. This dual-system design is engineered to address specific challenges faced in environments where corrosive gases are prevalent. The diaphragm pump component is strategically employed to evacuate gas molecules trapped within the rotary vane pump, thereby mitigating the exposure of the rotary vane pump to corrosive substances.

By reducing the duration and volume of corrosive gas exposure, the chemical hybrid pump significantly extends the operational lifespan of the rotary vane pump. This enhancement is crucial in maintaining the pump's efficiency and reliability, especially in demanding laboratory settings. The rotary vane pump, known for its high vacuum capabilities, retains its performance while benefiting from the protective measures implemented by the diaphragm pump.

The synergy between these two pump types not only preserves the integrity of the rotary vane pump but also ensures consistent high-vacuum performance. This makes the chemical hybrid pump an indispensable tool in laboratories where the handling of corrosive materials is a routine but critical task.

Molecular Pump

A molecular pump operates by leveraging the high-speed rotation of a rotor to impart momentum to gas molecules. This process effectively compresses the gas molecules, driving them towards the exhaust port. The gas molecules are then extracted by the front stage, ensuring efficient evacuation.

The molecular pump's mechanism is akin to a high-speed turbine, where the rotor's rapid rotation creates a directional force on the gas molecules. This force is crucial for achieving the necessary compression and subsequent extraction of the gas. The design of the molecular pump ensures that the gas molecules are not only compressed but also efficiently directed towards the exhaust port, enhancing the overall efficiency of the vacuum system.

In summary, the molecular pump's high-speed rotor plays a pivotal role in transferring momentum to gas molecules, facilitating their compression and subsequent extraction, thereby maintaining a high level of vacuum in the system.

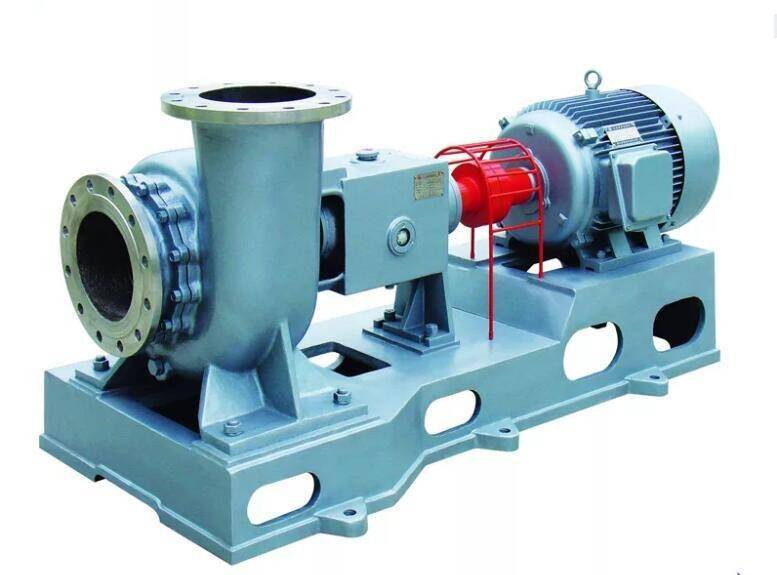

Circulating Water Vacuum Pump

A circulating water vacuum pump is a versatile piece of equipment capable of achieving an ultimate vacuum in the range of 2000-4000 Pa. When configured with an atmospheric ejector in series, this range can be significantly enhanced, reaching vacuums as low as 270-670 Pa. This enhanced capability makes it particularly suitable for applications requiring deep vacuum conditions, such as in certain chemical processes or laboratory setups.

In addition to its vacuum capabilities, the circulating water vacuum pump can also function as a compressor, a mode of operation commonly referred to as a water ring compressor. Operating within a low-pressure range of 1-2X10⁵ Pa gauge pressure, this dual functionality extends its utility across various laboratory and industrial settings. The water ring compressor mode is particularly advantageous in scenarios where low-pressure gas compression is needed, offering a reliable and efficient solution for such tasks.

This dual-purpose design not only optimizes space and resource utilization but also enhances the operational flexibility of the pump, making it a preferred choice in environments where both vacuum and compression functionalities are required.

Injection Pumps

Function and Mechanism

An injection pump is a sophisticated medical device that integrates a stepper motor, driver, screw, and bracket. This assemblage is designed to convert rotational motion into linear motion, facilitating the precise movement of the syringe piston. This mechanism is pivotal for both injection and infusion processes, ensuring high-precision, stable, and pulsation-free liquid transmission. The stepper motor, a key component, operates with a high degree of accuracy, allowing for controlled and incremental movements. The driver module synchronizes with the motor, providing the necessary electrical signals to maintain the desired motion.

The screw and bracket system work in tandem to translate the rotational force into linear displacement, pushing the syringe piston forward. This linear motion is crucial for the accurate delivery of fluids, whether for medicinal injections or infusion therapies. The entire system is engineered to minimize any potential for pulsation, ensuring a smooth and continuous flow of liquid. This precision is essential in medical applications where even minor deviations can have significant consequences.

In summary, the injection pump's design and operation are meticulously calibrated to meet the stringent demands of medical fluid delivery, providing a reliable and accurate solution for various healthcare needs.

無料相談はお問い合わせください

KINTEK LAB SOLUTION の製品とサービスは、世界中のお客様に認められています。弊社スタッフがどんなご質問にも喜んで対応させていただきます。無料相談にお問い合わせいただき、製品スペシャリストにご相談いただき、アプリケーションのニーズに最適なソリューションを見つけてください。