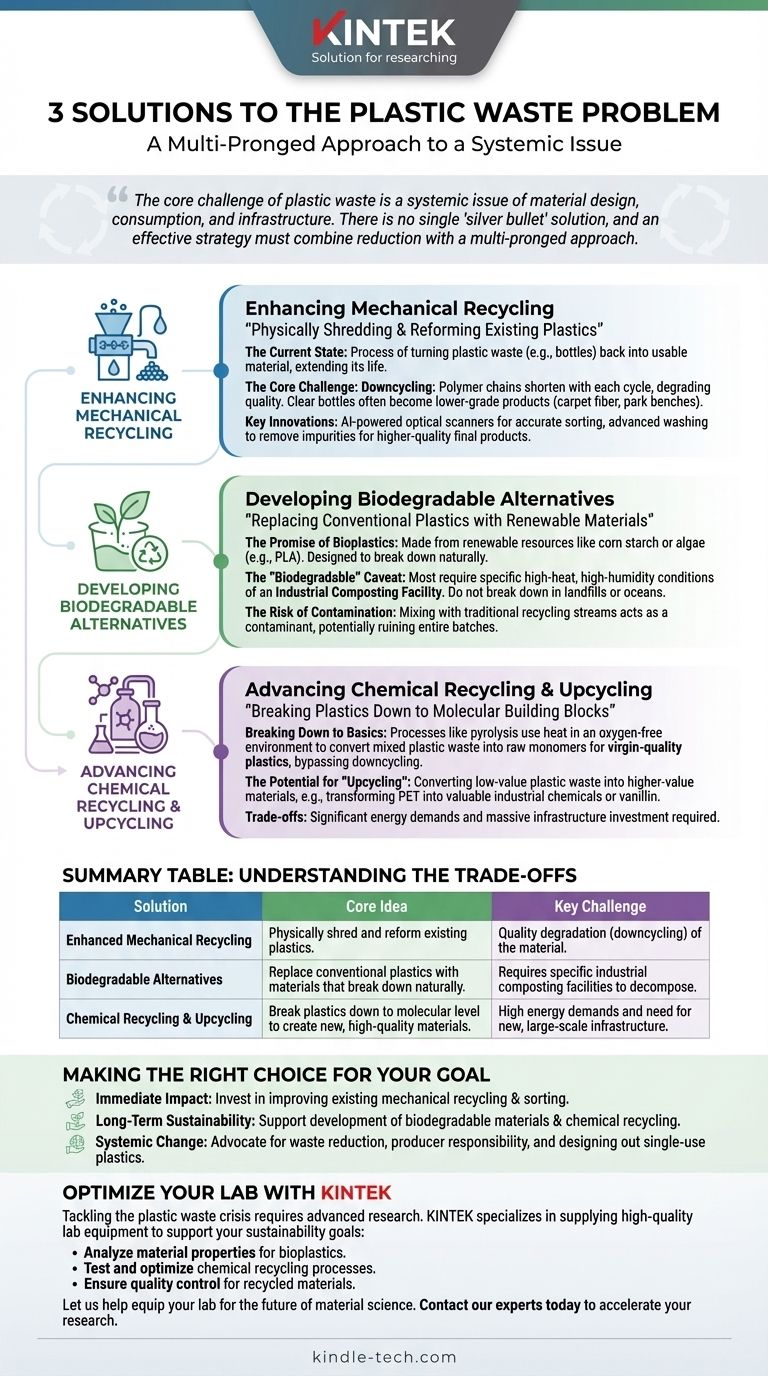

プラスチック廃棄物問題に対する3つの主要な解決策は、従来の機械的リサイクルの強化、生分解性代替品の開発と拡大、そして新しい形態の化学的リサイクルとアップサイクルの推進です。それぞれの方法は、既存の廃棄物の処理方法の改善から、使用する材料の根本的な変更に至るまで、プラスチックのライフサイクルの異なる段階を対象としています。

プラスチック廃棄物の中心的な課題は、単なる廃棄の問題ではありません。それは、材料設計、消費、インフラストラクチャにおけるシステム的な問題です。単一の「特効薬」は存在せず、効果的な戦略は、全体的な消費量を削減することと、避けられない廃棄物を管理するための多角的なアプローチを組み合わせる必要があります。

解決策1:機械的リサイクルの強化

機械的リサイクルは、プラスチック廃棄物を処理するための最も確立された方法です。これには、プラスチックを物理的に粉砕、洗浄、溶解し、新しいペレットに再成形して製造に使用する工程が含まれます。

機械的リサイクルの現状

これは、ほとんどの人がプラスチックボトルをリサイクル用の箱に入れることで認識しているプロセスです。目標は、そのボトルを再び使用可能な材料に変え、その寿命を延ばし、バージンプラスチックの必要性を減らすことです。

中心的な課題:ダウンサイクリング

機械的リサイクルの主な制限はダウンサイクリングです。プラスチックが溶かされて再加工されるたびに、ポリマー鎖が短くなり、品質と強度が低下します。これは、透明なペットボトルが再び透明なペットボトルになることはめったになく、カーペット繊維や公園のベンチのような低グレードの製品になる可能性が高いことを意味します。

改善のための主要なイノベーション

ダウンサイクリングと闘うために、努力はより良い選別と洗浄に集中しています。AIを活用した光学スキャナーは、人間の選別作業者よりもはるかに高い精度で異なる種類のプラスチックを識別・分離でき、汚染を低減します。高度な洗浄プロセスにより、不純物をより多く除去することもでき、より高品質な最終製品につながります。

解決策2:生分解性代替品の開発

このアプローチは、従来の石油由来プラスチックを、環境中で自然に分解するように設計された材料に置き換えることに焦点を当てています。

バイオプラスチックの可能性

バイオプラスチックは、トウモロコシデンプン、サトウキビ、藻類などの再生可能資源から作られます。最も一般的な例はポリ乳酸(PLA)で、使い捨てカップや食品容器によく使用されます。目標は、何世紀にもわたって環境中に残留しない材料を作ることです。

「生分解性」の注意点

重要な区別として、ほとんどの「生分解性」または「堆肥化可能」なプラスチックは、埋立地や海洋では分解されないという点があります。それらは、まだ広く利用可能ではない産業用堆肥化施設の特定の高温・高湿度の条件を必要とします。

汚染のリスク

もしPLAのようなバイオプラスチックが誤って従来のプラスチックリサイクルの流れに混入すると、汚染物質として機能します。それらは異なる化学組成と融点を持っているため、リサイクルされた石油由来プラスチックのバッチ全体を台無しにする可能性があり、明確なラベリングと消費者教育の必要性を浮き彫りにします。

解決策3:化学的リサイクルとアップサイクルの推進

化学的リサイクルは、化学プロセス、熱、または触媒を使用してプラスチックを元の分子構成要素に分解する新興技術群です。

プラスチックを基礎に分解する

熱分解のようなプロセスは、酸素のない環境で高温を使用し、混合プラスチック廃棄物を液体油または原材料モノマーに変換します。これらの原材料は、ダウンサイクリングの問題を完全に回避して、新しいバージン品質のプラスチックを作成するために使用できます。

「アップサイクリング」の可能性

より高度な概念がアップサイクリングであり、これは低価値のプラスチック廃棄物をより高価値の材料に変換することを目指します。例えば、研究者は、工学的な酵素と化学プロセスを使用して、PET(ペットボトルのプラスチック)を貴重な工業用化学物質や、バニラ風味の主成分であるバニリンに変換しています。

トレードオフの理解

単一の解決策も完璧ではなく、それぞれに、世界規模で効果的であるために対処しなければならない重大な課題が伴います。

エネルギーとインフラストラクチャのギャップ

高度な機械選別と化学的リサイクルの両方には、かなりのエネルギーと新しいインフラストラクチャへの大規模な投資が必要です。さらに、生分解性代替品のスケールアップには、それらを適切に処理するための産業用堆肥化施設の並行システムの構築が必要です。

根本原因:過剰消費

結局のところ、リサイクルと材料のイノベーションは、問題の「ライフサイクルの終わり」の部分のみに対処しています。使い捨てプラスチックの生産と消費を削減するための同時的かつ積極的な努力がなければ、これらの解決策は生成される廃棄物の膨大な量に追いつくのに苦労するでしょう。

あなたの目標に合わせた正しい選択をする

最適な道筋は、プラスチック廃棄物危機に対処するためにこれらの戦略を組み合わせることに依存します。

- 差し迫った影響に焦点を当てる場合: 既存の機械的リサイクルインフラストラクチャの改善と、循環している材料の価値を最大化するための公共の選別慣行の強化に投資します。

- 長期的な持続可能性に焦点を当てる場合: 真に生分解性のある材料の開発とスケーリング、および完全に循環型プラスチック経済を創造するために必要な化学的リサイクル技術を支援します。

- システム的な変化に焦点を当てる場合: 廃棄物削減を優先し、製品のライフサイクル全体に対して生産者に責任を持たせ、最初から使い捨てプラスチックを設計から排除するポリシーを提唱します。

成功する未来は、プラスチックへの依存を減らし、その管理方法を改善し、材料そのものの性質を革新する多面的な戦略にかかっています。

要約表:

| 解決策 | 中心的な考え | 主な課題 |

|---|---|---|

| 機械的リサイクルの強化 | 既存のプラスチックを物理的に粉砕・再成形する。 | 材料の品質低下(ダウンサイクリング)。 |

| 生分解性代替品 | 従来のプラスチックを自然に分解する材料に置き換える。 | 分解のために特定の産業用堆肥化施設が必要。 |

| 化学的リサイクルとアップサイクル | プラスチックを分子レベルまで分解し、新しく高品質な材料を作成する。 | 高いエネルギー需要と新しい大規模インフラストラクチャの必要性。 |

KINTEKで材料革新におけるラボの役割を最適化する

プラスチック廃棄物危機に取り組むには、高度な研究と正確な材料分析が必要です。新しい生分解性ポリマーの開発、リサイクルプロセスの最適化、化学的アップサイクルの経路の探求のいずれを行う場合でも、適切な実験装置を持っていることが成功の鍵となります。

KINTEKは、お客様の持続可能性の目標をサポートするための高品質な実験装置と消耗品の供給を専門としています。 私たちは、お客様が必要とするツールを提供します。

- バイオプラスチックの材料特性と分解率を分析する。

- 化学的リサイクルおよび熱分解プロセスのテストと最適化を行う。

- リサイクル材料および新しいポリマー配合の品質管理を保証する。

材料科学の未来に向けてラボを装備するお手伝いをさせてください。当社のソリューションがお客様の研究を加速し、循環型経済に貢献する方法について話し合うために、今すぐ専門家にご連絡ください。

ビジュアルガイド

関連製品

- ボタン電池収納ボックス バッテリーラボ用

- 実験用ITO FTO導電ガラス洗浄花かご用カスタム機械加工・成形PTFEテフロン部品メーカー

- 金属合金研磨罐和研磨球的实验室球磨机

- クリーニングラック用カスタムPTFEテフロン部品メーカー

- 酸・アルカリ耐性化学粉末用カスタムPTFEテフロン製スクープメーカー

よくある質問

- アルミニウムはスパッタリングできますか?高品質薄膜のためのプロセスを習得する

- 射出成形機で何が作れますか?高品質のプラスチック部品を効率的に大量生産

- 超低温フリーザーは科学研究においてなぜ重要なのでしょうか?サンプルの完全性と再現性の確保

- 反応性スパッタリング反応とは何ですか?高度な薄膜を精密に合成する

- 炉はんだ付けのプロセスとは?大量生産、高信頼性の接合を実現する

- 溶融塩腐食において、超高純度アルゴン グローブボックスが不可欠な理由とは?実験の完全性を保護する

- 熱分解の残留物とは何ですか?廃棄物を価値あるバイオ炭、バイオオイル、および合成ガスに変える

- 熱分解に最適な原料とは?生産量を最大化するための戦略的ガイド